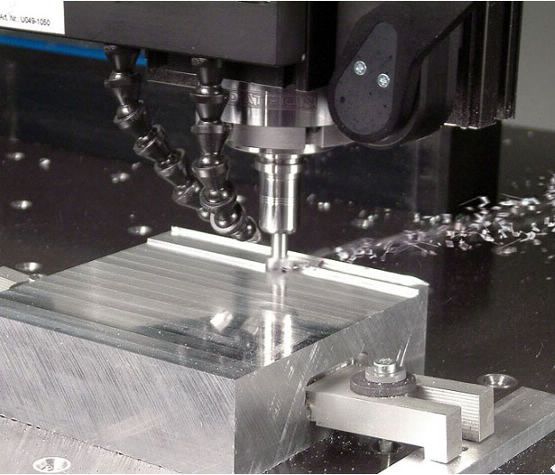

Precision Rapid Machining

As a professional rapid prototyping services Chinese supplier, we offer a wide range of rapid CNC machining services to produce precision prototypes for clients, including CNC milling, CNC turning, precise grinding and tapping, wire EDM cutting, sinker EDM, CNC engraving and laser cutting, 5 axis milling, screw machining, deep drilling, auto welding.

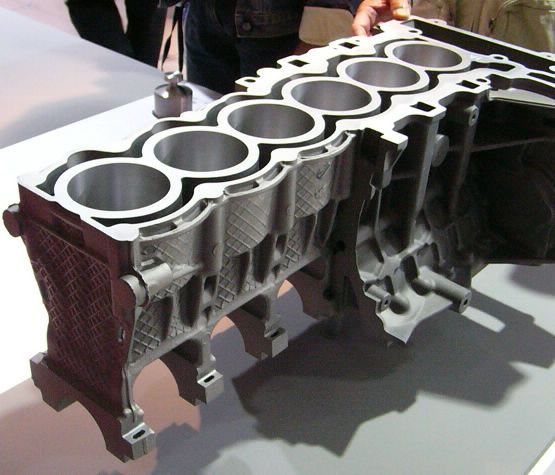

Rapid machining is a cost-effective, steady, accurate method of making prototypes from real production-grade materials, which is perfect for low-volume manufacturing, typically from 10 to 600 sets of components.