Precision Machined Parts

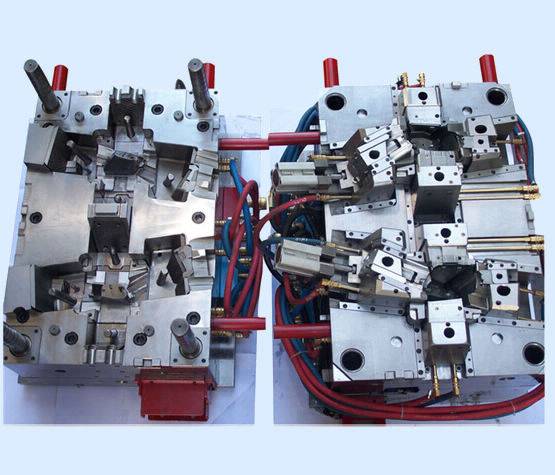

Precision machining is an efficient way to manufacture rapid prototype in China. As a leading rapid prototype China manufacturer, we can make high quality precision CNC machined parts in metals and plastics to serve a wide range of industries, such as automotive, motorcycle, medical devices, electronics, optical communication, sporting products, home applications, machinery, injection moulding, etc.

In a variety of steels can be used to produce metal prototypes, including stainless steel, copper, carbon steel, aluminium, titanium, nickel alloys, bronze, brass, 17-7 PH, etc.