Charlotte, NC (PRWEB) August 21, 2014

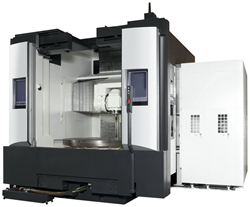

At IMTS 2014, Okuma will introduce its new VTM-2000YB multitasking CNC turning center, which provides heavy-duty construction for huge parts machining. The extreme rigidity and strong cutting capabilities of this machine make it excellent for machining huge diameter workpieces, such as those in the aerospace sector. The vertical architecture provides the benefit of “natural” element handling and outstanding chip fall, although taking up minimal floor space. At IMTS this machine will be using the full work envelope, cutting on a fan hub and engine case, featuring Super-NURBS and tooling from Sandvik, a member of Partners in THINC.

The VTM-2000YB requires the profitable notion of the VTM-200YB and advances the style to enhance rigidity, energy, B-axis range, speed and accuracy. It utilizes Okuma’s Thermo-Friendly Idea to enhance thermal stability, and has potent turning and milling capabilities with .001° B and C axes. This CNC turning center has 1.6 meters of Y-axis travel, combines powerful turning and milling functions for massive parts in the exact same machine and includes a 36 tool ATC for tool changing.

Important Specs of VTM-2000YB CNC Turning Center

Max Turning Diameter mm (in) Ø 2,000 (Ø 78.74″)

Spindle Nose Sort 380mm Flat Nose

Lathe Spindle Speed min⁻¹ 4~200

Milling Spindle Speed min⁻¹ 10,000

Fast Traverse (X/Y/Z) m/min (ipm) 32/32/32 (1,260/1,260/1,260)

Fast Traverse (B/C) rpm 19.5/20

For a lot more information on Okuma’s VTM-2000YB pay a visit to the Okuma Booth S-8500 at IMTS 2014.

About Okuma America Corporation

Okuma America Corporation is the U.S.-primarily based sales and service affiliate of Okuma Corporation, a planet leader in CNC (laptop numeric control) machine tools, founded in 1898 in Nagoya, Japan. The organization is the industry’s only single-supply provider, with the CNC machine, drive, motors, encoders, spindle and CNC manage all manufactured by Okuma. Okuma’s revolutionary and trustworthy technologies, paired with complete, localized service protection, permits customers to run constantly with self-assurance – maximizing profitability. Along with its sector-leading distribution network (largest in the Americas), and Partners in THINC, Okuma facilitates high quality, productivity and efficiency, empowering the customer and enabling competitive advantage in today’s demanding manufacturing environment. For much more data, check out http://www.okuma.com or adhere to us on Facebook or Twitter @OkumaAmerica.

About Partners in THINC

Partners in THINC is a collaboration network of a lot more than 40 business leaders who come together to resolve troubles and explore new productivity ideas for real-world producers. With the open architecture, Pc-primarily based THINC®-OSP handle as its nucleus, Partners in THINC brings specialized equipment, expertise and a commitment to give the ideal attainable integrated options to the finish-user. For far more details, visit http://www.okuma.com/partners-in-thinc.

###