The electron bar softening (EBM) measure was initially evolved at Chalmers University in Sweden during the 1990s. It is a powder-based technique sharing a great deal for all intents and purpose with SLS, however replaces the laser with an examined 4 kW electron pillar to create completely thick parts, like the china high precision cnc bronze custom made parts, despite the fact that porosity can only with significant effort be stayed away from because of the idea of the laser sintering measure.

This strategy ventures electrons at a large portion of the speed of light onto the powder surface, and the motor energy of the electrons ind uces dissolving. The electron pillar is when all is said in done more energy effective than a laser for conductive materials. The main EBM S12 machine was conveyed in March 2003 by Arcam. In Arcam’s CAD to Metal, materials accessible incorporate H13 apparatus steel, Arcam Low Alloy Steel, titanium amalgam (Ti-6A1-4V), and unadulterated titanium.

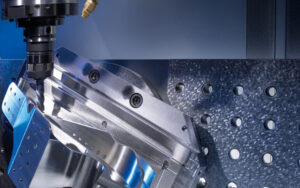

china cnc machining service,custom made metal cnc machining parts shows a section manufactured on an EBM-based machine. The part is planned in a 3D CAD program or made from a CT-output of a patient. The CAD document is spared as a STL record, which is utilized to set up the work. The STL record is cut into a SLC document and moved to the EBM framework. The part is developed by dissolving metal powder layer-by-layer with the EBM cycle. The outcome is a practical metal part, which is fit to be placed into activity.

In an EBM cycle as appeared in stainless steel big size casting part manufacturers china, parts are manufactured in a vacuum and at about 1000°C to restrict inward anxieties and improve material properties. The climate of the vacuum chamber is ordinarily 10- – 5 torr for Ti testimony, yet can differ down to 10 2 for different kinds of metals. A layer of metal powder is circulated over a stage in a vacuum chamber. To decrease the centralization of leftover burdens that cause mutilation in a created section, an electron-shaft firearm preheats the powder layer. After the preheating is done, the layer is specifically liquefied by expanding the pillar power or diminishing the speed. In the liquefying cycle, electrons are radiated from a fiber that is warmed to over 2500°C. The electrons are quickened through the anode to a large portion of the speed of light as appeared in china sheet metal prototyping manufacturers. An attractive focal point brings the pillar into center, and another attractive field controls the deflction of the bar.

At the point when the electrons hit the powder, active energy is changed into heat, which liquefies the metal powder. The force is constrained by controlling the quantity of electrons in the bar. The cooling cycle is likewise controlled to create very much characterized solidifying. Likewise with different cycles, the parts require some last machining after manufacture. The preparing in a vacuum gives a spotless climate that improves metal attributes.

When the primary layer is finished, the stage is then brought down, another layer of powder is conveyed and the cycle is rehashed until the part is finished. The subsequent part is completely thick. Finish heat treatment or machining, contingent upon the kind of metal powder or wire kept, is utilized to improve the surface completion. Complex shapes with overhangs and under-cuts can be worked with this procedure. Backing structures are not needed on the grounds that the free powder fills in as help for the following layers. In any case, amazingly complex inside math is the restricting variable of the EBM cycle.

The determinations of Arcam EBM S12 (4 KW) incorporate, 210 mmx 210 mm x 200 mm greatest form size, +0.4 mm precision, layer thickness of 0.05-0.2 mm, and dissolving speed of0.3- – 0.5 m/s. Figure 6.99 shows a case of the Ti-6Al-4V part delivered utilizing this cycle. The size of this part is 20 mmx 55 mmx 165 mm, and it took 6 h to fabricate. Figure 6.100 shows two perspectives on a tweaked tri-spine part made utilizing the EBM cycle. This is a Ti-6AI-4V part fabricated in4 h.

The EBM cycle may at last be relevant to a more extensive scope of materials than serious cycles and furthermore can possibly offer much better energy proficiency. A portion of its advantages incorporate the capacity to accomplish a high energy level in a limited pillar, vacuum soften quality to yield high quality properties of the material, vacuum climate to dispense with pollutions, for example, oxides and nitrides, and to allow welding in headstrong metals and mixes of disparate metals. When contrasted and laser sintering or dissolving, extra advantages remember higher effectiveness for producing the light emission bringing about lower power utilization just as lower upkeep and establishment costs, high real generally speaking force bringing about high form speeds, and the diversion of the shaft to abstain from moving parts bringing about high checking velocity and low support.

This article is from https://www.precisiontype.com