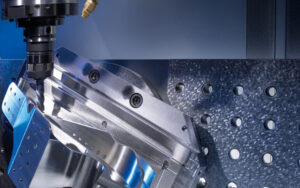

An immediate laser affidavit (DLD) or direct metal statement (DMD) measure is a laserssisted direct metal assembling measure that utilizes PC controlled lasers that, in hours, weld air blown surges of metallic powders into custom parts and assembling molds by china cnc turning laser carving parts manufacturers. A few cycles use wire rather than powder, however the idea is comparative. A delegate cycle is known as the Laser Engineered Net Shaping (LENS) measure. It utilizes CAD document cross-segments to control the shaping cycle created by Optomec Inc. The DLD cycle can be utilized by cnc rapid prototyping factory all through the whole item life-measure for applications going from materials examination to utilitarian prototyping to volume fabricating. An extra advantage is its special capacity to add material to existing parts for administration and fix applications. Powder-metal particles are conveyed in a gas stream into the focal point of a laser to frame a liquid pool of metal. It is a layer-by-layer added substance quick prototyping measure. The DLD cycle permits the creation of parts, forms, and bites the dust that are made out of the genuine end-material, for example, aluminum or device steel. At the end of the day, this delivers the high-temperature materials that are hard to make utilizing the conventional R P measures during china cnc precision machining.

The laser pillar is moved to and fro over the part and makes a liquid pool of metal where an exact stream of metal powder is infused into the pool to build its size. This cycle is the crossover of a few advancements: lasers, CAD, CAM, sensors, and powder metallurgy. This cycle likewise enhances different strategies for metalworking in that there is no waste material or subtractive cycles vital. It can likewise blend metals to explicit guidelines and determinations in a way that has never been conceivable.

cnc metal parts rapid prototyping suppliers china show two common LENS machines from Optomec Inc.. Focal point 750 System’s assemble volume is 12 in.3 though LENS 850-R System is 36x 60x 36 in.3. The manufacture rate is reliant on laser power. For instance, the construct rate for a 500 W laser is around 1 in./h. They utilize a laser sintering measure with the chance of having a sans oxygen climate. Their fundamental cycle is like a powder-bed measure where a laser sinters together a powder substance to frame parts. One advantage of the DLD system is the fine microstructure it makes while sintering the metal powder. This outcomes in high elasticity and high pliability that meet or surpass book esteems. As appeared in precision rapid prototype, the principle segments of a LENS system incorporate a Nd:YAG laser, a X-Y table to produce 2D movement of the workpiece, a technique for Z-pivot movement of laser, a powder-taking care of gadget, a laser-centering gadget, and a control system with CAD ability. The positional precision is about +0.01 in., and direct goal is about +0.0010 in. The surface completion is around 40- – 50 μm.

The significant LENS highlights and segments incorporate (1) Nd:YAG or fiber lasers (500 W to 2 kW) and affidavit or fix head; (2) airtight fixed Class I laser walled in area and detached pass-through chamber (vestibule); (3) programming: CAD (STL) information and cutting, robotized toolpath age, instruct and-learn fix programming, and cycle control; (4) PC controlled situating system (2.5- – 7 tomahawks of movement and fourth/fifth hub LaserW rist); (5) gas cleansing system (dri-train) and gas distribution system; (6) coordinated powder-conveyance system and powder recuperation system; (7) vision systems, liquefy pool checking and control system, and Z-stature observing and control system; (8) section or substrate warmer; and (9) measured part-taking care of system and palletized parts taking care of system.

This article is from https://www.precisiontype.com