Check out these precision parts engineering pictures:

Image from web page 165 of “The American railway its construction, development, management, and appliances” (1889)

Image by Web Archive Book Photos

Identifier: americanrailwayi00cool

Title: The American railway its construction, improvement, management, and appliances

Year: 1889 (1880s)

Authors: Cooley, Thomas McIntyre, 1824-1898 Clarke, Thomas Curtis, 1827-1901

Subjects: Railroads Railroads

Publisher: New York : C. Scribner’s sons

Contributing Library: University of California Libraries

Digitizing Sponsor: Web Archive

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Images From Book

Click here to view book online to see this illustration in context in a browseable on-line version of this book.

Text Appearing Ahead of Image:

^g- 34-—Camden & Amboy Locomotive, if

Text Appearing After Image:

THE CAB End OF A LOCOMOTIVE. – 131 exert a force on the piston equal to 38,175 pounds. This force isapphed alternately on every side of the piston, ten occasions in a second.The control of such forces requires mechanism which performs withthe utmost precision and with absolute certainty, and it is for thisreason that the speed and the economical operating- of a locomotivedepend so significantly on the proportions of the valves and the valve-gear by which the distribution of steam in the cylinders iscontrolled. The engraving (Fig. two)^^ on p. 133 represents the cab finish of alocomotive of the New York Central & Hudson River Railroad,looking forward from the tender, and shows the attachments bywhich the engineer works the engine.* This gives an notion ofthe number of keys on which he has to play in operating such amachine. There is room right here for little much more than an enumerationof the components which are numbered : 1. Engine-bell rope. 2. Train-bell rope. three. Train-bell or gong. 4. Lever for blowing whistle. 5. Ste

Note About Photos

Please note that these pictures are extracted from scanned page pictures that may possibly have been digitally enhanced for readability – coloration and appearance of these illustrations might not completely resemble the original function.

Lumps of Clay – component four of 4

Image by andrewtoskin

a photo comic

words by Andrew Toskin writing as Niccolo Florence

photography by hikaru starr

Men and women have been worrying too considerably about ebola. How lengthy till you catch children?

Copyright 2014. This operate is published under a Inventive Commons Attribution-NonCommercial-ShareAlike four. International License. Meaning essentially that you are cost-free to copy and share this perform — provided you credit us as the source — but not sell it. We are open to the idea of allowing industrial use, although just ask us initial. Reposts and remixes of this operate ought to attribute Niccolo Florence and hikaru starr, and link to curefornightmares.com

Text and photos were composited with GIMP. Full-size JPEGs are here on Flickr.

You’ll also uncover the present source files, plus different exported file formats at

the Internet Archive.

Here’s the original comic script:

Panel 1: HIK_4769 edit.JPG — silhouetted household on the

beach, with pier and sunset.

@Title and Byline

> Lumps of Clay

words by Niccolo Florence

photography by hikaru starr

curefornightmares.com

caption: I am no one’s father. (But?)

Panel two: IMG_0587.jpg — intense close-up on infant Ema’s face.

caption: But unless or till I succumb, it is my duty

to warn you that *youngsters are dangerous.* Keep away

from them whenever possible.

Panel 3: img_0811.jpg — Ema in a green hoodie in front of

one hundred dangling wooden placards.

caption: If you hear any pals or sexual partners talk about

how their “biological clocks are ticking,” leave the region

and wash your hands. If they *bring* any kids with them,

immediately evacuate all childless adults from the vicinity

and notify the regional authorities.

Panel 4: IMG_8976.jpg — Ema peeking about the bole of a

tree, with a creepy statue in the background.

caption: Most people are aware of the troubles children

can trigger, but many do not recognize the complete extent

of the danger, and so do not take sufficient

precautions. Fortunately, kids do come with a quantity

of warning indicators to ward off potential adult

caretakers.

Panel five: img_0276 roppongi edit.jpg — Ema’s face covered in red paint(?)

caption: Some of the greater recognized examples incorporate the

smells and noise…

Panel 6: HIK_1878.jpg — Ema standing on prime of a statue,

hunting down at us.

caption: Much less clear problems: They are also

codependent, irrational, evil creatures, unable to

negotiate or delay gratification. Anyone who shares a

household with a kid for lengthy will slave their days

away to slake ever-changing whims.

Panel 7: IMG_0452.jpg — Ema with a blue onesie over her

head. Most likely the cutest in the set.

caption: Kids are precision engineered to brainwash

you into loving them.

Panel 8: DSC_4229.jpg — Ema operating to a seesaw in a park.

caption: They will break your items, and break the

bank, and break your dreams, but practically nothing is worse than

the techniques they break your heart.

Panel 9: HIK_4865.jpg — Ema seen through a kaleidoscope.

caption: Kids are the most insidious of parasites:

The longer they stay with you, the deeper their

tendrils develop into you, cinching your ribs tighter and

tighter around your lungs, slithering into your

nervous method until you can scarcely believe about

anything else — and then they develop up and leave you.

Panel 10: HIK_0131.jpg — Ema at a shrine, pouring water

over one particular hand.

caption: And the hole they leave behind just bleeds and

bleeds…

Panel 11: HIK_9941.jpg — Ema wearing an auburn wig.

caption: This is the worst element of all, some thing that

even most in-patients who have tested good for

children may possibly not recognize for years.

Panel 12: HIK_9841.jpg — black and white Ema holding her

hand up to block the camera.

caption: Simply because you and your kid will drive each

other crazy. *Someone’s* life is receiving ruined, and

you will be terrified that it will not be yours.

caption: You will get in a stupid fight about creating the bed or

anything and you’ll both start off screaming and throwing

items, and next thing you know it hits me that I’m

becoming my mother, I’m perpetuating the cycle.

Panel 13: HIK_9310.jpg — Sick Ema in jacket and face mask.

caption: Young children are so fragile, so malleable. Soft

lumps of clay that mold to the contours of your hand

no matter how you try *not* to mold them.

caption: After all my mistakes, will she be okay? Will

she grow up all appropriate?

Panel 14: IMG_0567.jpg — singer with guitar and mic.

caption: Could the way she sings in the bathroom be a

sign that she’ll develop up to be a musician?

Panel 15: IMG_8976.JPG — A dancer.

caption: A dancer?

Panel 16: _HIK8727_014-2.jpg — model leaning over glass and handrail.

Panel 17: HIK_5078 raw edit.JPG — kabuki(?) performer on stage.

caption: Some sort of artist, surely.

Panel 18: HIK_1095.jpg — Ema, facing away from the camera.

caption: …Will she be pleased?

Panel 19: Huge, full-page shot. HIK_5285.JPG — Mysterious portrait of Ema

in a hat and daisy dress at evening, looking directly into the camera.

caption: …She isn’t even my daughter. I’ve only met

her once. But I currently adore her so considerably it hurts. I

be concerned possessing a kid of my own would *destroy* me.

End.

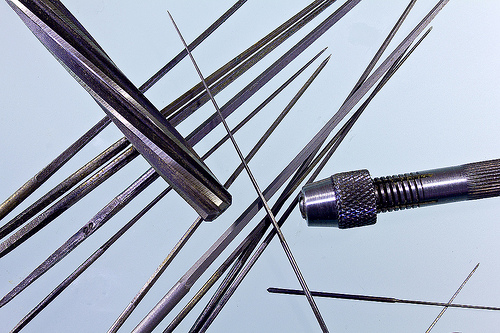

Pin Vice & Reamers/Broaches for Watch and Clock Creating

Image by tudedude

For scale the upper big reamer is 7mm and not element of the watch/clock maker pack Macro