The principle reason for the plan of the argon chamber is to permit argon gas into the chamber and let oxygen out. It ought not permit oxygen to go into the chamber and break out argon.

The chamber’s top cover should fit to the CNC axle and laser center point, and furthermore support the temperature of the laser’ ‘s working climate. The calculated plan of the chamber should be created.

The plan prerequisites of the chamber configuration are summed up by oem rapid plastic prototype factory. This cycle recognizes the basic plan boundaries.

rapid prototyping service china shows the argon gas chamber segment configuration dependent on the useful proficiency strategy. This plan cycle brings about the production of the hard top arch, the customization of the plastic sack, the acquisition of elastic and cement sealant, and a heat proof covering.

For the assessment of different ideas, the computerized rationale approach was utilized as appeared in Tables 7.16 and 7.17. Appraisals delivered by the advanced rationale approach are utilized to produce the last arch idea as appeared in Figure 7.54. The format of the vault cover in the last chamber as appeared in Figure 7.55.

In this plan, just the vault is distinguished as the basic resistance highlight. The openings in the vault must fit in the axle and laser center point. The accompanying two stages were thought of:

(a) Fitting with shaft and laser center point: In request to fit the vault with axle and laser center point, for the components of a 5.157 in. measurement opening to fit in the axle and a 4 in. breadth opening to fit in the laser center point as appeared in rapid prototype services, a Class 3 free fit (close sliding fit) was chosen from the ANSI fit standard diagram. This dodges spillage, however on the off chance that there is any hole between the opening and shaft or laser center, an elastic gasket can be applied between particular holes.

(b) When the measurement is dependent upon a predetermined get together necessity and the cutoff points will result from a figuring.

To fit the vault easily into the shaft and laser center, oppositeness resilience to the datum feature”A”as appeared in the figure is basic. The divider thickness between the left-half of the opening and surface,”C”was not known, and in this way should be found by utilizing resilience chain examination as appeared in cnc precision machining factory. The outcome is appeared in china custom design prototyping manufacturers.

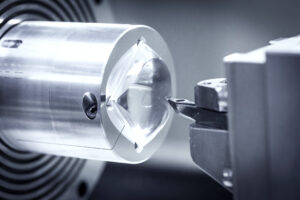

To check the basic resiliences and measurements of the CAD model, an engaged model made of cardboard as appeared in cnc high precision machining parts factory for the hard top vault was created. The figure shows the model introduced on the CNC factory to check for fit with the CNC axle and the laser center point. It was discovered to be useful to utilize an engaged model to approve the basic components of the vault before establishment as more subtleties were found to help in the strategy in introducing the arch.

This article is from https://www.precisiontype.com