Stereolithography (SLA) and Selective Laser Sintering (SLS) rapid prototyping strategies are mainstream in western nations,but in China CNC machining of pr…

Video Rating: 5 / 5

Month: January 2015

Kutta Technologies Continues Development on Revolutionary Autonomous Aerial Cargo Unmanned Resupply Program (AACUS)

(PRWEB) January 30, 2015

Kutta Technologies announced nowadays that they are a key member on the Office of the Naval Research’s (ONR) Autonomous Aerial Cargo Unmanned Resupply System (AACUS) group.

Kutta, operating in partnership with Aurora Flight Sciences, developed the Human Machine Interface (HMI) technologies for the Main Operating Base (MOB) and Combat Outpost (COP). The application Kutta created in the Phase I competitors runs on a commercial-off-the-shelf (COTS) iPad Mini and makes it possible for a Marine in the field to request needed supplies and denote the actual locations of exactly where to precisely drop them. When the request for supplies is made, it is routed via the program and the application autonomously generates a safe route to the landing zones. The secure route requires into account terrain, the airspace allocated to the mission, and other mission-particular parameters to make certain a profitable resupply. After the unmanned resupply aircraft is inside range, it scans the desired landing zone and negotiates with the COP operator to determine a appropriate landing place.

All the HMI devices have been developed employing thorough human factors engineering style methodologies recognized as Cognitive Process Analysis. “Our objective was to design and style an intuitive user interface that allows an operator to achieve a effective mission with only 15 minutes of education,” mentioned, James Bona, Software Developer for Kutta Technologies. Throughout the ONR flight demonstration, Kutta exceeded all HMI benchmarks and enabled the COP operator to flawlessly supervise 13 successful unmanned approaches and two planned wave-offs.

“Recently, Amazon® demonstrated a tiny unmanned aircraft in a controlled atmosphere that someday might provide books to your doorstep. We in fact did it with a huge helicopter, in winter condition, and with blowing snow. Our method could carry situations of books or health-related supplies that could save lives. This is no longer a dream. The technology is feasible these days.” – said Doug Limbaugh, CEO of Kutta Technologies.

In the Phase two, Kutta will integrate its Federal Aviation Administration (FAA) certifiable Ground Handle Station identified as the UGCS-178 into the MOB and further enhance the COP interface on an Android platform.

Kutta Technologies, Inc. is primarily based in Phoenix, AZ and is a leading developer of high reliability mission-essential application and systems for the aerospace sector. Kutta’s solution lines contain: The Bi-Directional Remote Video Terminal (BDRVT®), Unified Ground Control Station (UGCS-178), Kutta Rugged Laptop (KRC), and Manned / Unmanned Teaming Kit (MUM-178). For much more details please check out http://www.KuttaTech.com or call 1-866-574-9990.

Globe Automotive Composite Marketplace Discussed by MarketsandMarkets in Discounted Study Accessible at MarketPublishers.com

London, UK (PRWEB) December 09, 2014

Composites are widely employed in different market verticals, like the automotive market, owing to their properties, such as light weight and environmental resistance. The carbon fiber composites sector posts the fastest growth price, driven by improved use of these composites in the chassis and powertrain components application region. Exterior components kind the biggest application of automotive composites, which is forecast to be valued at around USD three.556 billion by 2019.

The international automotive composite industry is anticipated to attain a value of a lot more than USD 7.142 billion by 2019. The growth is driven by growing demand for fuel effective automobiles, and lowered weight and components consolidation possibilities offered by automotive composite, amongst other elements. However, high costs for composites and recyclability issues could pose a challenge to the future development in the market. The APAC area is the largest regional market place for automotive composites, accounting for just over 43% of the general demand for automotive composites in 2013. China is the region’s top customer of automotive composites.

Toray Industries Inc., Owens Corning, Johns Manville, SGL Group, Cytec Industries Inc., Koninklijke Ten Cate nv, Nippon Sheet Glass Co., Ltd., Jushi Group Co. Ltd., and Teijin Restricted are some of the essential automotive composite makers.

The discounted analysis report “Automotive Composite Market by Sort (Polymer Matrix Composite, Metal Matrix Composite, and Ceramic Matrix Composite) and by Application (Interior Elements, Exterior Components, Chassis & Powertrain Components and Others) – Worldwide Trends & Forecast to 2019” composed by MarketsandMarkets (M&M) is now obtainable at MarketPublishers.com.

Report Details:

Title: Automotive Composite Market place by Type (Polymer Matrix Composite, Metal Matrix Composite, and Ceramic Matrix Composite) and by Application (Interior Components, Exterior Elements, Chassis & Powertrain Elements and Other folks) – Worldwide Trends & Forecast to 2019

Published: November, 2014

Pages: 177

Price: US$ four,185.00

http://marketpublishers.com/report/machinery/auto_parts/automotive-composite-marketplace-by-sort-n-by-application.html

The investigation study analyses the international automotive composite marketplace, segmented by sort, application and geographic area, with present estimations and forecasts of the market volume and value via 2019. It identifies and scrutinizes the driving and limiting aspects, gives a detailed evaluation of possibilities, trends, pressing troubles, winning imperatives, and crucial challenges. The report also contains profiles of the top 13 companies and examines their recent finances, services and merchandise, competitive methods and insights, and latest developments.

Motives to Purchase:

Have a clear thought of the present standing of the planet automotive composite market place.

Obtain essential formation on the industry’s development in the previous.

Achieve a far better understanding of the key driving and limiting variables impacting the industry.

Recognize the most profitable growth opportunities in the automotive composite marketplace.

Turn into abreast of the hottest industry trends and concerns.

Know who stands exactly where in the planet automotive composite market.

Develop efficient competitive strategies on the basis of the prime-flight marketplace intelligence.

Track how the market place is projected to create through to 2019.

A lot more discounted reports by the publisher can be found at MarketsandMarkets page.

Discover A lot more China Sheet Metal Press Releases

Grooving and metal stamping approach

The technique and apparatus described herein make a tubular shelf post having a plurality of spaced apart annular grooves along the length thereof and stamped indicia on the outside surface of the post at various groove areas. A grooving and metal stamping roller is utilized to simultaneously groove and stamp the post with indicia, such roller becoming substantially larger in diameter relative to the post whereby a single roller revolution is adequate to groove and stamp the post thereby eliminating double metal stampings.

The present invention relates to the grooving and metal stamping of tubular shelf posts, and much more particularly to providing a post with spaced apart annular grooves along the length thereof and simultaneously metal stamping indicia on the outside surface ofthe post at the groove areas.

Adjustable metal shelving is well recognized, such shelving generally including a planar shelf member and four corner posts. The shelf member has corner supports at each of its corners, and these corner supports are adapted to receive and securelyhold the corner posts. The posts are fitted with post supports which hold the corner supports and the posts in a wedging secured arrangement. The posts usually contain spaced apart annular grooves along the length thereof, the grooves getting at fixeddistances along the vertical dimension of the post, and the post supports have inwardly directed projections created to match into the post grooves. In use, each post support is positioned with the projections thereof in a certain annular groove, eachat the same preferred vertical height along the post. The corner supports of the shelf member fit over the post supports in wedging engagement therewith to thereby horizontally locate the shelf member at the desired vertical height.

In many instances the annular grooves are spaced about one inch apart along the vertical dimension of the post thereby enabling a wonderful deal of shelf height adjustment. Even so, with a wide range of obtainable shelf heights, suitable shelf place isdifficult. With at least 4 post supports to position, it is often very hard to properly position each and every post support at the exact same preferred vertical height along the post. Time consuming trial and error procedures.

Accordingly, an object of the present invention is the production of shelving posts with spaced apart annular grooves along the length thereof in mixture with stamped indicia on the post at a variety of groove locations to facilitate effortless assemblyof the shelving.

Another object of the present invention is the provision of each apparatus and technique for simultaneously grooving and metal stamping posts, such apparatus and approach becoming simple to use and adhere to, effective and very effective.

In accordance with the present invention, in an apparatus for grooving a tubular post a major framework is offered with a pair of closely spaced drive rollers journaled to such primary framework. The axes of the drive rollers are parallel to oneanother and collectively define a assistance surface among the rollers for a tubular post. A motivator is connected to drive each and every of the rollers in the very same path and thereby rotate a tubular post in an opposite path. A grooving carriage is movablyconnected to the major framework, and a grooving roller is journaled to the carriage, the roller obtaining a plurality of spaced apart grooving tools along the length thereof. The axis of the grooving rollers is parallel to the axes of the drive rollers,and the carriage and grooving rollers are shifted toward and away from the drive rollers so that the grooving tools thereon engage a post supported by the drive rollers to thereby groove the posts. The improvement of the present invention is directed toa grooving roller which is substantially bigger in diameter than the post becoming grooved. Also, indicia metal stamping structure is arranged along the length of the grooving roller, such metal stamping structure comprising person dies, one particular die positioned neareach of substantially all of the grooving tools. Appropriate controls are arranged to let engagement of the grooving tools with a post throughout roughly a single revolution of the grooving roller to thereby get rid of double metal stamping of a post. Preferably, the metal stamping structure comprises individual dies substantially serial numbered.

In the process of the present invention, a tubular post is rotatably supoported, and spaced apart annular grooves are machined in the post along the length thereof. The improvement comprises the step of simultaneously metal stamping indicia next toeach of substantially all of the annular grooves to thereby recognize each annular groove. Preferably the metal stamping indicia comprises numbers arranged in a substantially serial manner.

The tubular post of the present invention has a plurality of spaced apart annular grooves on the outer surface thereon arranged along the length of the post. Stamped indicia is offered near every single of substantially all of the annular grooves tothereby identify each and every groove. Preferably the stamped indicia comprises numbers arranged in a substantially serial manner.

In accordance with the present invention, a grooving and metal stamping machine is supplied for machining spaced apart annular grooves in a tubular post and simultaneously therewith metal stamping indicia on the post at numerous groove areas. As explained elsewhere in this application, the annular grooves facilitate assembly of adjustable metal shelving which in its simplest type involves a planar shelf member and 4 corner posts. The stamped indicia of the present invention enables shelfassembly in an efficient and extremely effective manner by quicky and accurately locating positions on the posts.

xlnb.cn is a Manufacturer and suppliers of shower drain, sheet metal stamping, metal stamping, Equipment components by OEM/ODM service with diversified schemes.

Uncover Far more China Metal Stamping Articles

Report on China TFT-LCD Industry – Worldwide Business Analysis, Share, Size, Trends and Forecast 2014-2015

Albany, NY (PRWEB) December ten, 2014

The report delivers a detailed introduction to TFT-LCD, offers investigation-based information on upstream industries for the TFT-LCD market, supplies an evaluation on the overall TFT-LCD market, and delivers insight into the top TFT-LCD vendors. This report 1st introduces the TFT LCD sector prior to delving deep to supply a hugely researched analysis of the TFT LCD upstream industries. It also analyzes the overall industry and TFT LCD marketplace and then research 12 vendors.

Browse full report with total TOC at: http://www.researchmoz.us/global-and-china-tft-lcd-industry-report-2014-2015-report.html

The report states that in 2011, the marketplace saw a steep decline, but has exhibited improvements because 2012. According to the evaluation contained in the report, the TFT LCD market place is projected to peak in the very first half of 2015. Nonetheless, industry participants will have to be prepared for another decline in the TFT LCD market place by 2016. The report discusses how the slump in the TFT-LCD sector led to a slew of measures by vendors to adopt option technologies. For instance, vendors in South Korea, represented by tech giant Samsung, began to show an active interest in OLEDs. In Japan, organizations such as Toshiba, Hitachi and Sony began established a joint venture with a focus on building the LTPS technology. Considerably progress was also observed in the 4K HD technology sector in Taiwan. In China, new production lines had been constructed to reduce costs. Hence, all of these aggressive adjustments to counter the slump in the TFT LCD market have changed its dynamics.

However, the effects of these choices are now evident on the balance sheets of these vendors. For example, South Korean vendors who chose the OLED technology are now faced with a unique dilemma – electric-existing-primarily based OLED cannot be replaced by LCD, which is voltage-primarily based. With Samsung’s LCD company gradually witnessing a downslide, it will rank behind other vendors each in terms of revenue and shipment.

A comparison amongst the competitive dynamics of the LTPS technologies and LGZO technologies are an integral element of this report on the TFT LCD market—from the global as well as China perspective.

Browse far more connected reports to Show-Technologies market at: http://www.researchmoz.us/show-marketplace.htm

The prices of TFT LCD panels have been compared to provide the reader a clear image of the industry dynamics. The report also comprises an extensive list of tables and figures that offer an overview of the historical data of the TFT LCD marketplace, and offer insight into the future of this market place.

Browse Equivalent Reports:-

Transparent OLED Displays – 2014

http://www.researchmoz.us/transparent-oled-displays-2014-report.html

Metal Oxide TFT Backplanes for Displays 2014-2024: Technologies, Forecasts, Players

http://www.researchmoz.us/metal-oxide-tft-backplanes-for-displays-2014-2024-technologies-forecasts-players-report.html

For Much more Information Kindly Speak to:

E mail: sales@researchmoz.us

Blog: http://marketingresearchreport.wordpress.com/

Much more China Sheet Metal Press Releases

stamping sheet metal China

stamping sheet metal China Welcome to go to www.joinconn.com stamping sheet metal China,far more particulars pls speak to at lisa@dhjuwang.com , Hunting forward to he…

MEC Announces Changes to Senior Leadership Group

Mayville, Wis. (PRWEB) January 25, 2015

Mayville Engineering Organization, Inc. (MEC) today announced changes to its senior leadership team that will take spot with the retirement of Richard Nielsen, executive vice president of MEC.

These modifications are effective quickly:

Richard C. Nielsen, executive vice president, has elected to retire in June following 31 years of service with Center Manufacturing, Inc. and MEC.

Chad J. Mitts is promoted to executive vice president and will be accountable for the operations of MEC’s fabrications, efficiency structures, and tank business groups. He will also oversee the Greenwood, SC manufacturing facility.

Todd M. Butz is promoted to chief monetary officer.

Craig E. King is promoted to vice president of operations, functionality structures.

Frank I. Castanon is promoted to vice president of operations, tanks.

Mr. Nielsen joined Center Manufacturing in 1984 and held a number of senior management positions, including President and CEO of the business for 19 years prior to becoming acquired by MEC in December of 2012. His numerous achievements include acquisitions, operational expansions and improvements, and talent improvement. Mr. Nielsen also created sturdy relationships with major OEMs, resulting in tremendous sales growth for the firm.

“Dick Nielsen has a passion for buyer service and has been really useful in continuing to develop MEC,” said Robert D. Kamphuis, MEC chairman, president and CEO. “I genuinely appreciate his service to MEC and want him effectively in his retirement,” he added.

Mr. Mitts has been selected to succeed Mr. Nielsen. He previously held the position of vice president of approach, capital and continuous improvement. He has been instrumental in the development of MEC’s strategic strategy that will continue to drive development for the firm. He has a lot more than 20 years of professional expertise, including his preceding position of general manager of Meritor’s North American brake and driveline enterprise. Mr. Mitts holds a Bachelor’s degree in mechanical engineering from Michigan State University and a Master’s degree in mechanical engineering from the University of Illinois.

Mr. Butz began with MEC in 2008 as the assistant controller and has been promoted numerous occasions while assuming increasing responsibility. In his new function as chief economic officer, Mr. Butz is accountable for all of the accounting, budgeting and treasury activities for the company. He has created substantial knowledge at MEC and also draws from earlier finance and economic management positions at Mercury Marine and public accounting firm Schenck SC. Mr. Butz is a certified public accountant, holds a Bachelor of Company Administration and Accounting degree from Marian University, and a Master of Organization Administration degree from Oklahoma State University.

Mr. King joined the business in 1993 and has held several leadership positions, most not too long ago as plant manager of the Byron Center, Mich. operation. In his new function, he will lead the operations team for the company’s performance structures business group. Mr. King holds a Bachelor’s degree in engineering from Western Michigan University.

Mr. Castanon began with the business in 2009 and has held duty for the highly profitable Wytheville, Va. operations. He has comprehensive operations management experience in the industrial car segment. In his new function, Mr. Castanon is charged with major the tremendous development in the tank business, including the opening of MEC’s newest facility, which is located in Atkins, Va.

Far more details about MEC’s business-leading manufacturing and provide chain solutions can be identified by going to http://www.mecinc.com.

###

About Mayville Engineering Company

Headquartered in Mayville, Wis., MEC has become a manufacturing firm where employee shareholders are producing outstanding worth and help each day for their buyers and communities in which they reside and function. MEC serves the agricultural, industrial car, building, forestry, on/off road power sports vehicles, energy, military, and industrial markets. MEC’s processes incorporate comprehensive metal fabrication, laser and plasma cutting, stamping, forming, machining, welding, tube bending and forming, painting, polishing, brazing, cleaning, assembly and kitting, prototyping, product testing and validation, fluid level indicators, stoppers, engine tubes, suction tubes, hydraulic tubes, discharge tubes, fill tubes, high temp coatings, metal encapsulated insulation, fuel tanks, air brake tanks, air intake and exhaust systems. The firm’s core competencies incorporate collaborative product development, design and style for manufacturability, engineering and design review, project management and buyer service. MEC operates 17 facilities with over two,one hundred,000 square feet of manufacturing in Michigan, Mississippi, South Carolina, Virginia and Wisconsin. A lot more details can be found at http://www.mecinc.com.

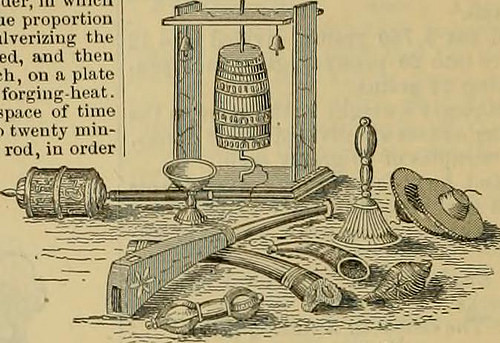

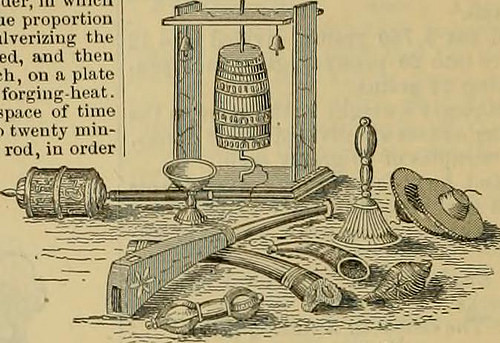

Image from web page 883 of “Knight’s American mechanical dictionary : a description of tools, instruments, machines, processes and engineering, history of inventions, common technological vocabulary and digest of mechanical appliances in science and the ar

A couple of good china mechanical engineering pictures I identified:

Image from web page 883 of “Knight’s American mechanical dictionary : a description of tools, instruments, machines, processes and engineering, history of inventions, general technological vocabulary and digest of mechanical appliances in science and the ar

Image by World wide web Archive Book Pictures

Identifier: knightsamericanm02knig

Title: Knight’s American mechanical dictionary : a description of tools, instruments, machines, processes and engineering, history of inventions, common technological vocabulary and digest of mechanical appliances in science and the arts

Year: 1882 (1880s)

Authors: Knight, Edward H. (Edward Henry), 1824-1883

Subjects: Industrial arts Mechanical engineering

Publisher: Boston : Houghton, Mifflin and Company

Contributing Library: NCSU Libraries

Digitizing Sponsor: NCSU Libraries

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Images From Book

Click right here to view book on the web to see this illustration in context in a browseable on the internet version of this book.

Text Appearing Before Image:

ia, Ceylon, Burniah, Siam, China,and Japan. Divided as it is from the mainland ofthe continent, and superior to China as Japan ap-pears to be, there is considerably aflinity in between theirforms of civilization and government, and in manydetails of their manners and religion. In Thibet the art of praying has been brought to a high stateof advancement. It is no longer challenging to utter long pr.aycrs.for the pmyer written on a piece of paper or a leaf and fastenedto a wheel is understood to be uttered as soon as for every single revolutionof the wheel. The motion of the written is the mechanicalequivalent of the vocal exerci^^e driven in a direction contrary to that of theapparent motion of the sun. This is probablyimportant. The barrfl corresponds to the htatls and ro-.taries of regions fartlier west. The rosary, infact, is borrowed from the East. These mechanical developments of mentalemotions are the all-natural outgrowths of a cer-tain grade of civilization. In an additional machine, two modest rings are Fig. 3931.

Text Appearing After Image:

Note About Images

Please note that these images are extracted from scanned web page pictures that might have been digitally enhanced for readability – coloration and look of these illustrations might not completely resemble the original operate.

Image from page 362 of “Transactions” (1852)

Image by Net Archive Book Photos

Identifier: transactions51nort

Title: Transactions

Year: 1852 (1850s)

Authors: North of England Institute of Mining and Mechanical Engineers, Newcastle-upon-Tyne North of England Institute of Mining and Mechanical Engineers, Newcastle-upon-Tyne. Report of the Committee upon mechanical coalcutting, 1905

Subjects: Mineral industries Mechanical engineering

Publisher: Newcastle-upon-Tyne

Contributing Library: Gerstein – University of Toronto

Digitizing Sponsor: University of Toronto

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Pictures From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Ahead of Image:

ins, 76, 147-Wtixkhaus, —, sprinkling dusty gal-leries at Anna and Carl shafts of the Kolner Bergwerks-Verein colliery at Altenessen, abs. 85.Witwatersrand mines, dangers, abs. 107. 10 itfDEX. Wood, W. O., Sussmann electric miners lamp. —Discussion, 145.Wood, suitable for pit-props, abs. 70.Woodhorn colliery, 117. Woodhorn colliery, apparatus for closing prime of upcast-shaft, 121.W orks and workmen,Simplon tunnel, 126.Wyssotzky, N., gold-mines of Kochkar, southern Urals, abs. 16. X. Xenotime, and new yttrium-mineral, | hussakite, Brazil, connection, abs. 33. Younu, W. G., submarine oil-wells in California, abs. 39. Z. Zeiller, R., coal-fields of Shansi andcentral Honan, northern China, abs 24. Zinc-bearing ores, Sadtler process fortreating, abs. 99. Zinc-iron gahuite, Sweden, Helsing-land, abs. 21. Zinc lead deposits, United States ofAmerica, Arkansas, south-west, abs.64. Zinc-ores, Africa, Algeria, abs. 28. ZwALinvENBEKG, A. von, modifiedSiemens and Halske approach, abs. 96. i »

Text Appearing After Image:

£ sirofi^i^^MWp I? iff a two if fpir

Note About Images

Please note that these pictures are extracted from scanned web page images that may have been digitally enhanced for readability – coloration and look of these illustrations may possibly not perfectly resemble the original operate.

Most current Cnc Engineering Services News

Mitsubishi Electric to Consolidate Improvement and Manufacture of PLC and …

Mainly produces PLCs, operator panels, inverters, AC servos, CNC, EDM, laser processing machines, robots, 3-phase motors, magnetic motor starters, transformers (oil-filled, mold, dry and gas), magnetic motor drives, and FA platform. Employed two,538 …

Read far more on SYS-CON Media (press release)

Welding Engineer

Exclusive Systems Design and style, Inc., a premier Engineering Solutions, Software program Improvement and Talent Management Acquisition provider has over 60 direct-employ positions, in-home positions, or on-internet site positions available. Most of the possibilities are in the …

Study more on MyFox Detroit

Yavapai College providing new food, wine, hotel, engineering programs

Faculty member Tara O'Neill reported on the college's service understanding program. Far more than 450 students have place in more than eight,400 hours of neighborhood service by means of the system, which combines classroom instruction and community service to support …

Read much more on Prescott Everyday Courier

WCC Board of Trustees hold meeting

Pre-hire instruction at the CNC Instruction Center is slated to begin February two. GE Aviation will be adding 105 new jobs in its West Jefferson facility over the subsequent three years and investing practically $ 60 million in equipment and buildings. Nearly 50 of the …

Read far more on Jefferson Post

CNC Engineering Europe Ltd Machining solutions in Poland

info@neweurope-eng.co.uk Office: 00 44 () 1727 860721 Mobile: 00 44 () 7891 220 836 … www.cncengineeringeurope.co.uk Copyright CNC Engineering Europe Ltd…

Video Rating: five / five