Bridgeville, PA (PRWEB) April 16, 2014

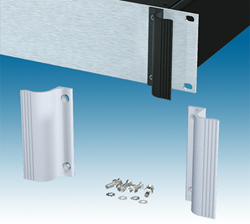

Metal electronic enclosures manufacturer METCASE has added extruded handles to its range of accessories for custom 19” front panels, rack circumstances and chassis.

The new ergonomic handles make it simpler to match the front panels or chassis into cabinets or take away them during installation and maintenance, speeding up servicing occasions.

These handles have been first launched as a distinctive function of the bestselling COMBIMET range that METCASE introduced last year.

And they proved to be so common that customers began asking if they had been accessible to retro-fit to other 19” enclosures.

Now METCASE has created it easier for buyers to order them by formally adding them to the accessories variety.

The simple but efficient building of the handles tends to make it very effortless to fit them to custom 19” chassis or rack situations and 19” front panels made by other companies.

The handles are obtainable as standard in 5 sizes: 1U, 2U, 3U, 4U and 6U. The width and depth of every manage is 1.574” x 1.181”. Other U sizes – such as 5U – can be supplied on demand. Two colors are offered, Light Gray (RAL 7035) and Black (RAL 9005). Custom colors are obtainable to order.

Each deal with kit consists of two handles plus a complete set of fixings: M4 x 16 mm screws, M4 lock washers and M4 nuts. These let simple assembly to any size of panel or chassis.

Their extrusion-primarily based format means they can be cut to any desired size, decreasing the expense of customization.

METCASE Vice President, Sales, Sean Bailey mentioned: “COMBIMET has been such a good results story for us and the handles are just one particular facet of that.

“We worked extremely hard to make COMBIMET a higher quality, great value proposition and the marketplace rewarded our efforts by generating it our number a single 19” rack case,” he added.

METCASE, the metal enclosures division of OKW, manufactures 4 ranges of rack mount situations – VERSAMET, COMBIMET, UNIMET and METTEC – plus nine other ranges of desktop, portable, wall mount enclosures and diecast boxes.

The 4 19” rack enclosure ranges have been developed to provide various panel configurations:

COMBIMET instances with fixed front, removable leading, base and rear

VERSAMET instances with fixed front, removable base and rear

METTEC (removable front)

UNIMET (removable front, base and rear)

Accessories for them incorporate ABS case feet which are available either with or with out tilt legs. Like the handles, the feet are an extremely well-liked retro-match choice.

They come in 3 colors: Light Gray (RAL 7035), Off White (RAL 9002) and Black (RAL 9005). Every kit includes four feet, four rubber inserts and 4 self-tapping screws.

Other accessories for 19” circumstances contain:

front panels – anodized aluminum, 1U x 19”, 2U x 19”, 3U x 19”, 3U x 10.5”

19” mounting kits – with four M6 caged nuts, 4 M6 screws and four ABS plastic cup washers (Gray or Black)

front panel trims – 1.969″ & 1U case three.346″ & 2U four.724″ 3U case five.905″

PCB mounting kits – 10 x M3x10 mm molded pillars ten x M3x6 mm countersink screws.

METCASE enclosures can be completely customized. Solutions contain produced-to-measure sizes internal mounting plates and brackets CNC milling, drilling and punching painting and anodizing silk-screen or tampo printing of legends and logos.

For additional specifics, please view the METCASE website or speak to Sean Bailey, Tel: 800-965-9872.

-Ends-

Notes For Editors

METCASE specializes in the design and manufacture of high top quality aluminum enclosures for the electronics business. The METCASE range has been created to permit for modifications to be carried out with ease.

Special sizes and versions of the enclosures can be developed in batch quantities from as tiny as ten units. This flexibility offers style engineers with an exceptional range of choices for creating new merchandise and variations.

METCASE is a division of the OKW Group.

OKW Enclosures, Inc

3000 Old Pond Road

Bridgeville, PA 15017

Phone: 412 220 9244

Fax: 412 220 9247