Verify out these china prototype photos:

Soviet Truck ZIS-150. 1947 – 57. Грузовой автомобиль ЗИС-150.

Image by Peer.Gynt

The ZIS-150 was a Soviet truck. In 1947 it replaced the ZIS-5 on assembly line. ZIS-150 with each other with GAZ-51 was the major Soviet truck of ’50s, judging by their quantity. The cabin of ZIS-150 was related with the cabin of International Harvester KR11 truck. In 1957, the base ZIS-150 model was replaced by ZIL-164, which differed outwardly only by vertical grille bars and bumper. ZiS-150 was also manufactured in Braşov, Romania amongst 1954-1960 beneath SR-101 badge at "Steagul Rosu" (Red Flag) and in China below Jiefang CA-ten badge at Very first Automobile Functions. At least one particular prototype was constructed in North Korea under the the name "Chollima".

Years of production: 1947 – 1957

General production: 774615 units

Specifications4x2 4000 kg truck

Engine: 90 hp/2400 rpm, 6-cyl, 5555 cc

Bore/Stroke: 101.six/114.3 mm

Length: 6,720 mm (264.6 in), width: 2,385 mm (93.9 in), height: 2,180 mm (85.eight in)

Wheelbase: four,000 mm (157.5 in), rear axis clearance: 265 mm (10.4 in)

Front wheel track: 1,700 mm (66.9 in)

Rear track: 1,740 mm (68.5 in)

Turning radius on front outer wheel: eight. m (26.2 ft)

Compression ratio: 6.

Clutch: twin disk, dry

Gearbox: five speeds

Weight (with out load): 3,900 kg (8,598 lb)

Maximal speed (loaded, highway): 65 km/h (40 mph)

Tyres: 9,00×20 inches

Fuel capacity: 150 L (40 US gal 33 imp gal)

Fuel consumption: 29 L/one hundred km (9.7 mpg-imp eight.1 mpg-US)

Inside Google’s Project Loon — providing every single cell phone direct access to the Web

Image by jurvetson

With the prospective to bypass telcos and government censors. It will be fascinating to see how the fly-over rights negotiations go for China and nations that want to manage the connections to their men and women, for political or organization reasons.

Google can very easily avoid the Northern Hemisphere altogether to commence. They hope to have all main cities in the Southern Hemisphere covered 90% of the time later this year. They have 7 balloon up at present, but have had as several as 70 up at one time. The ultimate international remedy is 10’s of thousands.

The only navigation manage is vertical (adding or removing air as ballast the helium remains in a separate part of the balloon) so they can catch or avoid the prevailing winds.

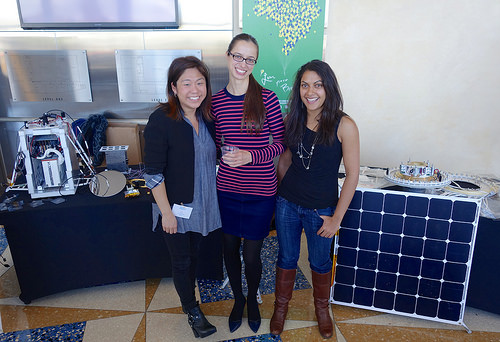

Here you see some of the engineering team. I am rooting for them to support democratize access across the planet, and supply a competitive alternative to the limited broadband choices in many parts of the world today.