A couple of nice mechanical engineering china images I found:

Image from web page 615 of “Railway mechanical engineer” (1916)

Image by Net Archive Book Pictures

Identifier: railwaymechanica95newy

Title: Railway mechanical engineer

Year: 1916 (1910s)

Authors:

Subjects: Railroad engineering Engineering Railroads Railroad vehicles

Publisher: New York, N.Y. : Simmons-Boardman Pub. Co

Contributing Library: Carnegie Library of Pittsburgh

Digitizing Sponsor: Lyrasis Members and Sloan Foundation

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Pictures: All Pictures From Book

Click right here to view book on the internet to see this illustration in context in a browseable online version of this book.

Text Appearing Just before Image:

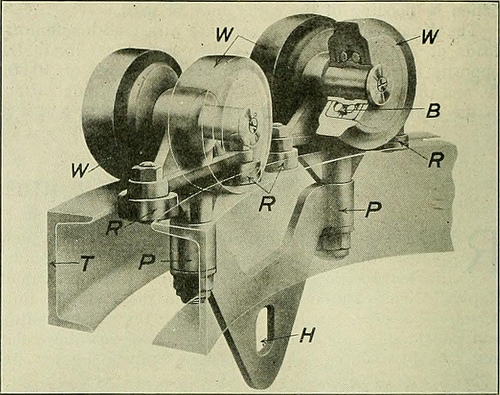

s into an open freightcar or automobile truck. The method can also be readilywired ought to an electric hoist be desired in spot of chainfalls. The track is built and shipped and can be erected assingle units, thus drastically lowering the price of erection. Specific two-wheel, four-wheel, or eight-wheel trolleys are supplied,the four-wheel type being illustrated in Fig. 2. There are ball-bearing wheels W and guide rollers R which run betweenthe toes of the channels, practically eliminating friction andmaking it difficult for the wheels to bind against the track ,&mtm WS^J! JB49JP ^five | wzw m m Fig. 1—View of Overhead Trolley Method with Universal Switches when rounding the curves. Carbonized steel ball bearingsare shown at B, pivots at P and the hoist connection at H.The trolley runs on the level leading of the channel tracks and is designed to swing in the identical 18 in. radius curves. Thefact that this track is built from standard rolled channelsor can be built from I-beam sections exactly where long spans and

Text Appearing After Image:

Fig. 2—Phantom View of Short Turn Trolley greater strength is necessary, tends to make it straightforward to obtain fromlocal stocks and less complicated to erect. The operation of this systemlightens the function and makes it considerably a lot more easy and favorablefor the workmen handling material, thereby decreasing laborturnover and rising the efficiency of unskilled labor.The system is being manufactured and sold by the WhitingCorporation, Harvey, 111. Unique Hydraulic Driving Wheel Press THE Hydraulic Press Manufacturing Firm, MountGilead, Ohio, designed and built the particular hydraulicpress, illustrated, which was lately sold by the Mc-Carter Cooper Business, New York, to the Compagnie Gen-eral De Chemins De Fer & Tramways en Chine, Pekin,China. This press is employed for forcing driving wheels on or off amongst strain bars is 84 in. and in between ram and resistancehead is 108 in. maximum. This may possibly be decreased to 78 in.by moving the resistance head, which is mounted on wheels.The press is also equipped with a belt

Note About Photos

Please note that these photos are extracted from scanned page photos that might have been digitally enhanced for readability – coloration and appearance of these illustrations may possibly not perfectly resemble the original perform.

Image from web page 67 of “Railway mechanical engineer” (1916)

Image by World wide web Archive Book Pictures

Identifier: railwaymechanica93newy

Title: Railway mechanical engineer

Year: 1916 (1910s)

Authors:

Subjects: Railroad engineering Engineering Railroads Railroad automobiles

Publisher: New York, N.Y. : Simmons-Boardman Pub. Co

Contributing Library: Carnegie Library of Pittsburgh

Digitizing Sponsor: Lyrasis Members and Sloan Foundation

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click right here to view book on the web to see this illustration in context in a browseable on the internet version of this book.

Text Appearing Before Image:

ult, nowadays the Continental—European—design of locomotive is predominant in China.On some of the lines, notably these beneath English and,hitherto, German influence, not a locomotive other than thosebuilt in accordance with the prevailing design frequent tothe nation financing the railway was bought or even con-sidered, either for initial or sub.sequent equipment—at leastup to the time of the outbreak of the war. Only in the caseof the Chinese financed and operated railway have Ameri-can builders been offered a cost-free hand, with the result that anAmerican design and style was adopted, and a thorough standardiza-tion of energy effected. Out of the 638 locomotives in ser-vice on all lines at that time only 15 five/2 per cent had been ofAmerican desi.gn and manufacture and on the Engli.sh,Belgian, and French lines, which operated at that time 365locomotives, or around 60 per cent of the total, onlveight, or approximately 2.2 per cent had been of American de-sign and manufacture.—Eastern Engineering.

Text Appearing Soon after Image:

THE BLOMQUIST-ECK HORIZONTALBORING MILL The operating efficiency of any horizontal mill and drilldepends entirely upon its potential to operate upon all classesof work at the highest speeds and coarsest feeds practicable,and at all occasions to generate a completed product of dependableaccuracy. The Blomquist-Eck Machine Firm, Cleve-land, Ohio, in designing its new horizontal boring mill, hasdeveloped these points to a higher degree by combiningrigidity, accuracy, a suitable range of selective speeds and

Note About Pictures

Please note that these pictures are extracted from scanned page photos that may have been digitally enhanced for readability – coloration and look of these illustrations may not completely resemble the original work.