Auburn Hills, MI & Bedford, NH (PRWEB) September 30, 2014

Patti Engineering, Inc., a leader in control systems integration, today announced it will expand its collaboration with McClellan Automation Systems, a company that styles and builds custom production automation manufacturing equipment. McClellan Automation Systems, primarily based in Bedford, NH is an advanced manufacturing systems company that styles and builds custom production automation gear.

On the heels of using Patti Engineering for the 1st time to effectively total a huge contract for a significant U.S. manufacturer, McClellan Automation Systems will continue to collaborate with Patti Engineering as an professional manage systems integration resource. It became apparent during the execution of this project, that the companies’ combined locations of knowledge are extremely complementary and can be leveraged to generate new business possibilities moving forward.

Earlier this month McClellan Automation Systems was named Organization NH Magazine’s quickest expanding private company for 2013. From 2010 to 2013, McClellan Automation Systems grew by 1,750%, thanks in component to diversification from the company’s roots in the healthcare device manufacturing industry to the customer products and life science industries.

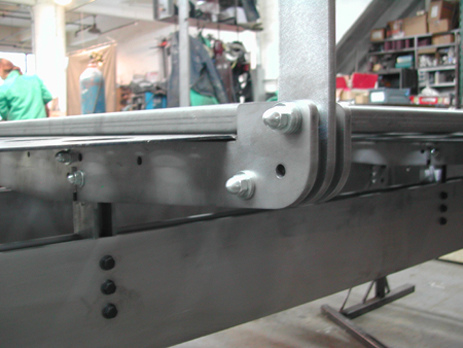

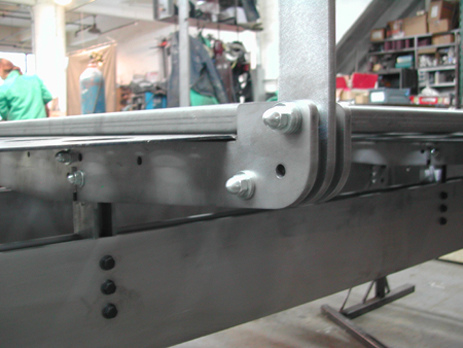

McClellan Automation Systems initial learned about Patti Engineering when the firm needed added Mitsubishi automation authorities to help with a project developing complicated machine lines requiring higher-precision programming of Mitsubishi robots and Programmable Logic Controllers (PLCs). Gibson Engineering, New England’s Mitsubishi supplier, recommended Patti Engineering, for the further engineering assistance. Patti Engineering is a Mitsubishi Authorized Integrator, with exceptional expertise in Mitsubishi’s automation platform – a rare skill set amongst U.S. control technique integrators. Patti Engineering supplied 5 specialist engineers more than a five month period to assist with completion of the project.

“The complexity of this project essential engineers with years of expertise designing intricate machine lines. The size of this project required far more manpower than we could supply on quick notice, so we contracted Patti Engineering to extend our group,” said McClellan’s Chief Executive Officer, Ray Ritter. “Working with Patti Engineering has been a seamless process. Our experience and capabilities go hand in hand and we are looking forward to finishing a lot of more difficult and rewarding projects together in the future.”

Michigan primarily based Patti Engineering maintains a satellite workplace near Boston, MA and has been creating a presence in the New England area. Patti Engineering is a CSIA Certified handle method integrator offering high-caliber engineering and software improvement services in the fields of industrial automation and shop floor IT options. Patti Engineering’s locations of expertise coupled with McClellan Automation Systems’ expertise in the design of custom automation equipment for high-precision discrete part assembly and process automation, offer a much more useful resource for makers interested in utilizing sophisticated automation technologies to streamline operations and acquire a competitive edge.

Patti Engineering’s Executive Vice President, Sam Hoff commented, “McClellan is an innovator, taking on the type of challenging projects Patti Engineering thrives on. We anticipate a long and mutually beneficial connection.”

To inquire with Patti Engineering and McClellan Automation Systems about a project, pay a visit to http://www.pattiengineering.com/make contact with.

About Patti Engineering, Inc.

Patti Engineering, Inc. is a CSIA Certified control systems integration company offering higher-caliber engineering and software development solutions. Patti Engineering’s technical experience in electrical handle and data systems supplies turnkey handle systems integration for design/develop, upgrade/retrofit and asset/power management projects. Industrial automation, production intelligence and shop floor IT options services contain: project management, electrical engineering, hardware design, hardware procurement, application improvement, installation, calibration, start-up testing, verification, documentation, coaching and warranty help. Customer satisfaction and project accomplishment earned the firm Handle Engineering Magazine’s 2013 Program Integrator of the Year. For more details, visit http://www.pattieng.com.

Patti Engineering Media Get in touch with:

Georgia Whalen

Director of Advertising

gwhalen(at)pattieng(dot)com

978-697-2664

About McClellan Automation Systems

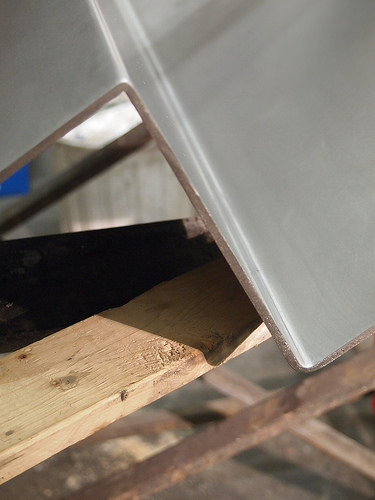

Founded in 1989, McClellan Automation Systems is an advanced manufacturing systems business that styles and builds custom production automation gear. A privately owned company, McClellan supplies clientele across the U.S.A. with solutions ranging from small, proof-of-principle projects to full-size turnkey automated systems. McClellan supplies custom automation equipment for higher-precision discrete part assembly, approach automation and internet handling. Founder and Chairman James W. McClellan appears to the future by investing in firms establishing emerging technologies, “Our goal is to continue the diversification into new markets and sophisticated manufacturing systems.” For a lot more information on McClellan Automation Systems, go to http://www.mcclellan-automation.com.

McClellan Automation Systems Media Get in touch with:

Director of Advertising and marketing

McClellan Automation Systems

603-644-2369 x6129