Check out these precision engineering company photos:

Steven F. Udvar-Hazy Center: Boeing B-29 Superfortress “Enola Gay” (view into nose cockpit)

Image by Chris Devers

See far more photographs of this, and the Wikipedia article.

Specifics, quoting from Smithsonian National Air and Space Museum | Boeing B-29 Superfortress "Enola Gay":

Boeing’s B-29 Superfortress was the most sophisticated propeller-driven bomber of Globe War II and the very first bomber to house its crew in pressurized compartments. Despite the fact that developed to fight in the European theater, the B-29 located its niche on the other side of the globe. In the Pacific, B-29s delivered a range of aerial weapons: traditional bombs, incendiary bombs, mines, and two nuclear weapons.

On August six, 1945, this Martin-built B-29-45-MO dropped the very first atomic weapon employed in combat on Hiroshima, Japan. 3 days later, Bockscar (on display at the U.S. Air Force Museum close to Dayton, Ohio) dropped a second atomic bomb on Nagasaki, Japan. Enola Gay flew as the advance weather reconnaissance aircraft that day. A third B-29, The Wonderful Artiste, flew as an observation aircraft on each missions.

Transferred from the United States Air Force.

Manufacturer:

Boeing Aircraft Co.

Martin Co., Omaha, Nebr.

Date:

1945

Country of Origin:

United States of America

Dimensions:

Overall: 900 x 3020cm, 32580kg, 4300cm (29ft 6 5/16in. x 99ft 1in., 71825.9lb., 141ft 15/16in.)

Materials:

Polished general aluminum finish

Physical Description:

Four-engine heavy bomber with semi-monoqoque fuselage and higher-aspect ratio wings. Polished aluminum finish general, regular late-World War II Army Air Forces insignia on wings and aft fuselage and serial quantity on vertical fin 509th Composite Group markings painted in black "Enola Gay" in black, block letters on decrease left nose.

Extended Description:

Boeing’s B-29 Superfortress was the most sophisticated, propeller-driven, bomber to fly during World War II, and the initial bomber to home its crew in pressurized compartments. Boeing installed extremely sophisticated armament, propulsion, and avionics systems into the Superfortress. For the duration of the war in the Pacific Theater, the B-29 delivered the initial nuclear weapons utilised in combat. On August 6, 1945, Colonel Paul W. Tibbets, Jr., in command of the Superfortress Enola Gay, dropped a extremely enriched uranium, explosion-type, "gun-fired," atomic bomb on Hiroshima, Japan. Three days later, Major Charles W. Sweeney piloted the B-29 Bockscar and dropped a hugely enriched plutonium, implosion-variety atomic bomb on Nagasaki, Japan. Enola Gay flew as the advance climate reconnaissance aircraft that day. On August 14, 1945, the Japanese accepted Allied terms for unconditional surrender.

In the late 1930s, U. S. Army Air Corps leaders recognized the want for extremely lengthy-variety bombers that exceeded the performance of the B-17 Flying Fortress. Numerous years of preliminary studies paralleled a continuous fight against these who saw restricted utility in creating such an costly and unproven aircraft but the Air Corps issued a requirement for the new bomber in February 1940. It described an airplane that could carry a maximum bomb load of 909 kg (2,000 lb) at a speed of 644 kph (400 mph) a distance of at least eight,050 km (5,000 miles). Boeing, Consolidated, Douglas, and Lockheed responded with design and style proposals. The Army was impressed with the Boeing design and issued a contract for two flyable prototypes in September 1940. In April 1941, the Army issued yet another contract for 250 aircraft plus spare parts equivalent to an additional 25 bombers, eight months prior to Pearl Harbor and nearly a year-and-a-half prior to the very first Superfortress would fly.

Among the design’s innovations was a extended, narrow, higher-aspect ratio wing equipped with big Fowler-variety flaps. This wing style allowed the B-29 to fly extremely fast at high altitudes but maintained comfortable handling characteristics throughout takeoff and landing. Far more revolutionary was the size and sophistication of the pressurized sections of the fuselage: the flight deck forward of the wing, the gunner’s compartment aft of the wing, and the tail gunner’s station. For the crew, flying at extreme altitudes became a lot far more comfortable as stress and temperature could be regulated. To protect the Superfortress, Boeing created a remote-controlled, defensive weapons method. Engineers placed 5 gun turrets on the fuselage: a turret above and behind the cockpit that housed two .50 caliber machine guns (4 guns in later versions), and an additional turret aft close to the vertical tail equipped with two machine guns plus two more turrets beneath the fuselage, each and every equipped with two .50 caliber guns. One of these turrets fired from behind the nose gear and the other hung further back near the tail. One more two .50 caliber machine guns and a 20-mm cannon (in early versions of the B-29) had been fitted in the tail beneath the rudder. Gunners operated these turrets by remote manage–a accurate innovation. They aimed the guns utilizing computerized sights, and each and every gunner could take handle of two or a lot more turrets to concentrate firepower on a single target.

Boeing also equipped the B-29 with advanced radar gear and avionics. Based on the sort of mission, a B-29 carried the AN/APQ-13 or AN/APQ-7 Eagle radar program to aid bombing and navigation. These systems have been accurate enough to permit bombing by way of cloud layers that completely obscured the target. The B-29B was equipped with the AN/APG-15B airborne radar gun sighting technique mounted in the tail, insuring precise defense against enemy fighters attacking at night. B-29s also routinely carried as a lot of as twenty various varieties of radios and navigation devices.

The initial XB-29 took off at Boeing Field in Seattle on September 21, 1942. By the finish of the year the second aircraft was prepared for flight. Fourteen service-test YB-29s followed as production began to accelerate. Creating this sophisticated bomber essential massive logistics. Boeing constructed new B-29 plants at Renton, Washington, and Wichita, Kansas, even though Bell built a new plant at Marietta, Georgia, and Martin constructed 1 in Omaha, Nebraska. Each Curtiss-Wright and the Dodge automobile firm vastly expanded their manufacturing capacity to construct the bomber’s strong and complicated Curtiss-Wright R-3350 turbo supercharged engines. The system essential thousands of sub-contractors but with extraordinary work, it all came together, despite main teething problems. By April 1944, the initial operational B-29s of the newly formed 20th Air Force started to touch down on dusty airfields in India. By May, 130 B-29s had been operational. In June, 1944, much less than two years following the initial flight of the XB-29, the U. S. Army Air Forces (AAF) flew its initial B-29 combat mission against targets in Bangkok, Thailand. This mission (longest of the war to date) referred to as for 100 B-29s but only 80 reached the target location. The AAF lost no aircraft to enemy action but bombing benefits were mediocre. The very first bombing mission against the Japanese main islands because Lt. Col. "Jimmy" Doolittle’s raid against Tokyo in April 1942, occurred on June 15, once again with poor final results. This was also the initial mission launched from airbases in China.

With the fall of Saipan, Tinian, and Guam in the Mariana Islands chain in August 1944, the AAF acquired airbases that lay a number of hundred miles closer to mainland Japan. Late in 1944, the AAF moved the XXI Bomber Command, flying B-29s, to the Marianas and the unit started bombing Japan in December. However, they employed high-altitude, precision, bombing tactics that yielded poor benefits. The higher altitude winds had been so strong that bombing computers could not compensate and the climate was so poor that rarely was visual target acquisition achievable at high altitudes. In March 1945, Major General Curtis E. LeMay ordered the group to abandon these tactics and strike rather at night, from low altitude, using incendiary bombs. These firebombing raids, carried out by hundreds of B-29s, devastated much of Japan’s industrial and financial infrastructure. But Japan fought on. Late in 1944, AAF leaders selected the Martin assembly line to produce a squadron of B-29s codenamed SILVERPLATE. Martin modified these Superfortresses by removing all gun turrets except for the tail position, removing armor plate, installing Curtiss electric propellers, and modifying the bomb bay to accommodate either the "Fat Man" or "Little Boy" versions of the atomic bomb. The AAF assigned 15 Silverplate ships to the 509th Composite Group commanded by Colonel Paul Tibbets. As the Group Commander, Tibbets had no specific aircraft assigned to him as did the mission pilots. He was entitled to fly any aircraft at any time. He named the B-29 that he flew on 6 August Enola Gay following his mother. In the early morning hours, just prior to the August 6th mission, Tibbets had a young Army Air Forces upkeep man, Private Nelson Miller, paint the name just under the pilot’s window.

Enola Gay is a model B-29-45-MO, serial quantity 44-86292. The AAF accepted this aircraft on June 14, 1945, from the Martin plant at Omaha (Positioned at what is today Offut AFB close to Bellevue), Nebraska. Following the war, Army Air Forces crews flew the airplane for the duration of the Operation Crossroads atomic test program in the Pacific, despite the fact that it dropped no nuclear devices for the duration of these tests, and then delivered it to Davis-Monthan Army Airfield, Arizona, for storage. Later, the U. S. Air Force flew the bomber to Park Ridge, Illinois, then transferred it to the Smithsonian Institution on July four, 1949. Even though in Smithsonian custody, the aircraft remained stored at Pyote Air Force Base, Texas, between January 1952 and December 1953. The airplane’s last flight ended on December 2 when the Enola Gay touched down at Andrews Air Force Base, Maryland. The bomber remained at Andrews in outside storage till August 1960. By then, concerned about the bomber deteriorating outdoors, the Smithsonian sent collections staff to disassemble the Superfortress and move it indoors to the Paul E. Garber Facility in Suitland, Maryland.

The staff at Garber began functioning to preserve and restore Enola Gay in December 1984. This was the biggest restoration project ever undertaken at the National Air and Space Museum and the specialists anticipated the operate would call for from seven to nine years to total. The project in fact lasted nearly two decades and, when completed, had taken roughly 300,000 work-hours to complete. The B-29 is now displayed at the National Air and Space Museum, Steven F. Udvar-Hazy Center.

Steven F. Udvar-Hazy Center: Boeing B-29 Superfortress “Enola Gay”, with Lockheed P-38J-10-LO Lightning

Image by Chris Devers

Quoting Smithsonian National Air and Space Museum | Lockheed P-38J-10-LO Lightning :

In the P-38 Lockheed engineer Clarence "Kelly" Johnson and his team of designers created one of the most productive twin-engine fighters ever flown by any nation. From 1942 to 1945, U. S. Army Air Forces pilots flew P-38s more than Europe, the Mediterranean, and the Pacific, and from the frozen Aleutian Islands to the sun-baked deserts of North Africa. Lightning pilots in the Pacific theater downed much more Japanese aircraft than pilots flying any other Allied warplane.

Maj. Richard I. Bong, America’s leading fighter ace, flew this P-38J-10-LO on April 16, 1945, at Wright Field, Ohio, to evaluate an experimental method of interconnecting the movement of the throttle and propeller manage levers. Even so, his correct engine exploded in flight before he could conduct the experiment.

Transferred from the United States Air Force.

Manufacturer:

Lockheed Aircraft Company

Date:

1943

Country of Origin:

United States of America

Dimensions:

Overall: 390 x 1170cm, 6345kg, 1580cm (12ft 9 9/16in. x 38ft 4 5/8in., 13988.2lb., 51ft ten 1/16in.)

Supplies:

All-metal

Physical Description:

Twin-tail boom and twin-engine fighter tricycle landing gear.

• • • • •

Quoting Smithsonian National Air and Space Museum | Boeing B-29 Superfortress "Enola Gay":

Boeing’s B-29 Superfortress was the most sophisticated propeller-driven bomber of World War II and the initial bomber to home its crew in pressurized compartments. Even though created to fight in the European theater, the B-29 located its niche on the other side of the globe. In the Pacific, B-29s delivered a range of aerial weapons: conventional bombs, incendiary bombs, mines, and two nuclear weapons.

On August six, 1945, this Martin-built B-29-45-MO dropped the very first atomic weapon utilised in combat on Hiroshima, Japan. Three days later, Bockscar (on display at the U.S. Air Force Museum close to Dayton, Ohio) dropped a second atomic bomb on Nagasaki, Japan. Enola Gay flew as the advance weather reconnaissance aircraft that day. A third B-29, The Great Artiste, flew as an observation aircraft on each missions.

Transferred from the United States Air Force.

Manufacturer:

Boeing Aircraft Co.

Martin Co., Omaha, Nebr.

Date:

1945

Nation of Origin:

United States of America

Dimensions:

All round: 900 x 3020cm, 32580kg, 4300cm (29ft six 5/16in. x 99ft 1in., 71825.9lb., 141ft 15/16in.)

Materials:

Polished overall aluminum finish

Physical Description:

Four-engine heavy bomber with semi-monoqoque fuselage and high-aspect ratio wings. Polished aluminum finish all round, common late-Globe War II Army Air Forces insignia on wings and aft fuselage and serial quantity on vertical fin 509th Composite Group markings painted in black "Enola Gay" in black, block letters on reduce left nose.

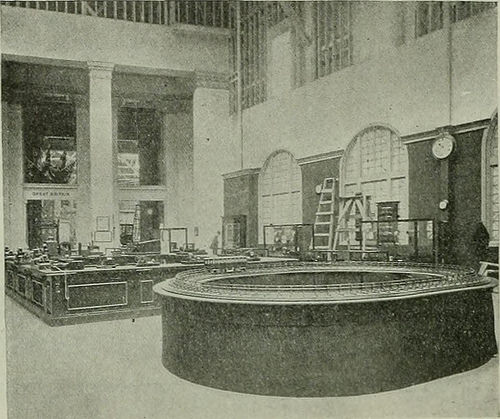

Image from page 1050 of “Electrical globe” (1883)

Image by Web Archive Book Images

Identifier: electricalworld43newy

Title: Electrical globe

Year: 1883 (1880s)

Authors:

Subjects: Electrical engineering

Publisher: [New York McGraw-Hill Pub. Co., and so forth.]

Contributing Library: Engineering – University of Toronto

Digitizing Sponsor: University of Toronto

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click here to view book on the internet to see this illustration in context in a browseable on-line version of this book.

Text Appearing Prior to Image:

he Regular Underground CableCompany close to the northwest corner entrance. The installation of ing was in its infancy. About the walls of the exhibit spaces arehung photographs of the pioneers and their early work. The Jumbodynamo, produced by the Edison Machine Functions, direct-connected toa high-speed engine, forms an intriguing comparison with themodel of the General Electric io,ooo-hp Niagara generator, which 1036 ELECTRICAL World and ENGINEER. Vol. XLIII, Xo. 22 is across the aisle. The 1st Edison electric locomotive vith itspassenger automobile shows in a graphic way the progress in transportationmade since 1880. The photograph of the British section reveals the splendid displayof electrical and scientific instruments created by the English manu-facturers. Most of these instruments have been tested and havecertificates from Lord Kelvins laboratory or the National PhysicalLaboratory. The Basic Post Workplace makes an superb displayof the telegraphic apparatus used in Fantastic Britain. Kelvin and

Text Appearing Soon after Image:

FIG. six.—ENGLISH EXHIBIT. James White, of Glasgow, and Muirhead & Co., of Kent, have casesof galvanometers, condensers, common cells, ammeters, voltmetersand other instruments of precision. In the foreground may beseen a working model of Behrs monorail and high-speed vehicle asauthorized by act of Parliament for the railway amongst Manchesterand Liverpool, to be operated at a speed of no miles per hour. The greater component of the sp-ace of the Wagner Electric Business, ofSt. Louis, in Section 9. is occupied by the a variety of applications ofsingle-phase alternating-existing motors. This includes the standardform, enclosed, semi-enclosed and back-geared types, from }4 to 35hp. The notable feature of these motors is their beginning beneath

Note About Pictures

Please note that these pictures are extracted from scanned web page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may possibly not completely resemble the original operate.