CNC Machines are personal computer controlled, just like any other CNC machine tools. It can be programmed to do a range of things, such as grinding, cutting and drilling. CNC lathe wood or metal, based on the project you happen to be carrying out. This machine can support lessen your production time and boost your enterprise profitability in the end.

Wood lathe can not only be utilised for timber, such as brass, and aluminum supplies. Other components supplied by the metal operating lathe or milling machine. Varieties provide limitless creative possibilities. So, what type of path you can place your enterprise in the future?

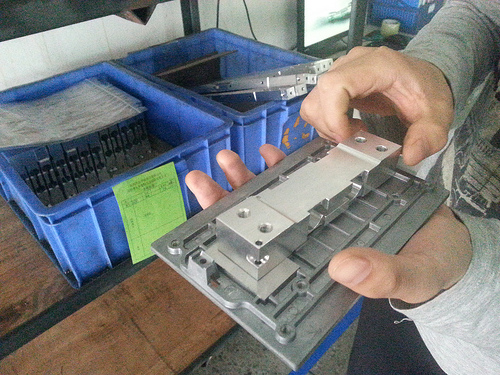

Huge firms from the tiny shops, a lathe, any individual can. Regardless of whether you need portable or fixed machines, the decision is yours. Modest shops can use the CNC machine tools for precise and complex cuts, stair railings, table legs, chair legs, and so forth. When you are completed, the product will be beautiful, symmetrical, worth in the end.

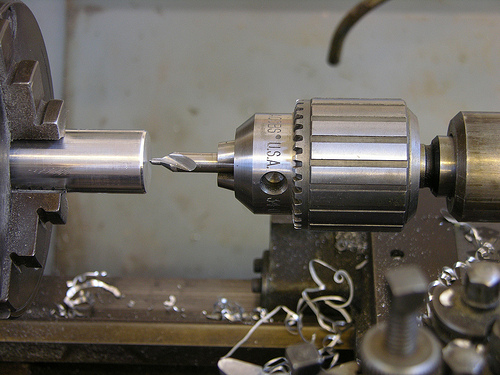

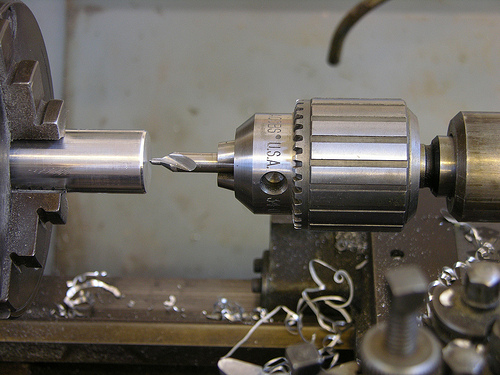

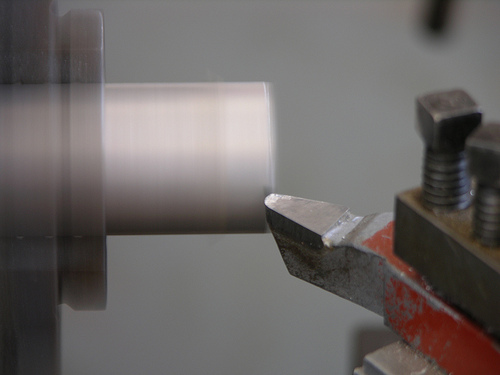

This process is named rotation. The material permits several shapes and cuts made open, whilst keeping the symmetry of the final product. A excellent diameter from the prime to the bottom portion will be cut to the needed specifications. Never ever been any simpler to attain this level of design and style and production of the final product, as it is now.

Metal processing CNC lathe another possibility. You want to develop a need to have a circular motion? If this is the case, CNC lathe is the best machine, so you have some part. Any material can be employed. The material, however, be able to stand up and turn to the process of the computer software program program continues to rotate until the final.

Operators want to do is a want for programming the machines necessary for the production of merchandise, it and the material is loaded into the machine specifications. The machine does not rest. Machine running on the X and Y axes. This is a fantastic use, if you do not consider numerous of the same item, the same size and shape of a lot of decoration. Laptop software plan will continue to operate the machine, in the circle rotation soon after rotation has been reached, until the required specifications.

From the tapered finish of the contour shape, this machine can do it all. CNC lathe your organization to give specific hyperlinks, further actions, you are hunting for technologies and save time. Bear in mind, no matter what kind of material you use, CNC lathe can use it as lengthy as it is to stand up for the duration of rotation.

CNC lathe, it can do for you, if you have any additional inquiries, please get in touch with your dealer to give the folks of this technology. They will be capable to additional answer any concerns you have and you in the proper direction. We also supply shaping and slotting machines and milling machine as per your require.

A land drag I built to sell required a lift mechanism, so I decided to put a window regulator motor on a trailer jack and make my personal linear actuator. This mea…

Video Rating: 4 / five