Shenzhen, China (PRWEB) November 25, 2014

HLH Prototypes, supplying speedy prototype injection molding solutions in China is recognized for its high precision, speed and finest high quality. They make the finest high quality plastic components utilizing fast plastic molding services from their ISO accredited facilities in China. The prototype injection molding procedure is price powerful with quickly delivery or real components in actual supplies.

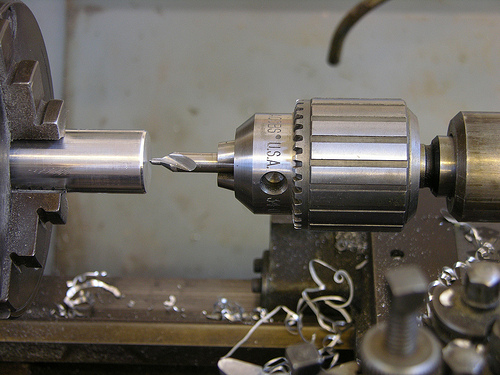

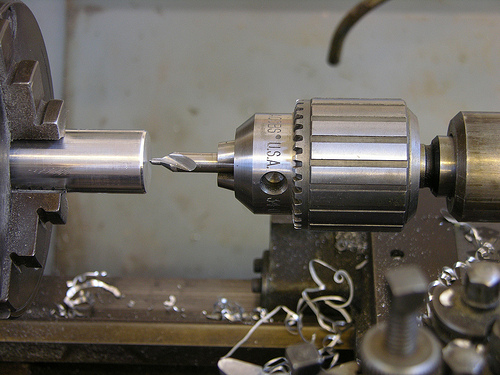

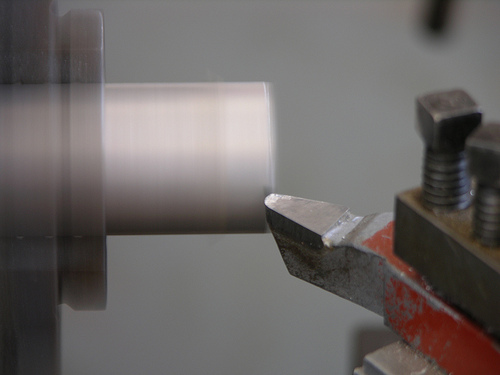

“HLH Prototypes uses a trademarked CNC machining approach to let us to manufacture genuine injection mold tools utilised for generating genuine components in thermoplastics making use of injection molding,” says Jack Cheng HLH’s rapid tooling manager. Their recent investment in gear has drastically enhanced the speed of delivery of their prototype tooling manufactured items. They work with their clients to understand parts from all manner of industries which includes customer electronics, household, medical and automotive parts.

To make sure the lowest attainable expense, the plastic molding services are provided HLH Prototypes are tailored to the fast/prototyping tooling requirements. The top quality is high and the delivery is super quick.

“HLH Prototypes is taking advantage of automated techniques of machining and speedy prototyping solutions in China to increase speed and top quality of product,” Jack mentioned. With recent investments in gear like $ 60,000 for an Oxford instruments PMI master pro, HLH Prototypes has drastically improved their rapid prototyping QC approach.

HLH Prototypes will be attending many events in 2015 to showcase the advancement in their solutions. In March 2015 they will attend the TCT Show + Personalized which the leading event dedicated to 3D printing, additive manufacturing and item development. In June 2015, they will be exhibiting at the Big M show at the Cobo Center in Detroit, MI in the United States. The Large M Event showcases breakthrough technologies and applications that will sustain and develop leadership for mass manufacturing. Later in the year in October they will be in the UK for the TCT + Customized show also committed to the 3D printing, additive manufacturing and solution improvement. When it comes to rapid injection molding solutions, they have handful of competitors.

About The Organization:

HLH Prototypes has years of engineering knowledge to grow to be a leader provider of CNC machining, additive manufacturing/3D printing, speedy prototyping, injection molding, plastic molding and fast tooling services. They have lately invested in $ 60,000 piece of equipment to advance the level of services they provide, specifically the Oxford instruments PMI master pro. Their customers are massive and small businesses from around the globe for all their machining, prototyping and contract manufacturing. For speedy prototype service in China, HLH Prototypes stands in forefront.

Get in touch with Info:

Workplace: 1801 Xing Ji Building, Xin Sha Road, Shajing, Baoan, Shenzhen, China, 518125

Factory: 2nd floor, Building 6, Hua Fa Industrial Park, Fu Yuan 1st Road, Fuyong, Baoan, Shenzhen, China

Tel: +86-755-82569129 (ext 817 for English)

Fax: +86-755-82569136

information@hlhprototypes.com Fax No ()1753684199, Accounts ()1753689910. Ext-103

# # #