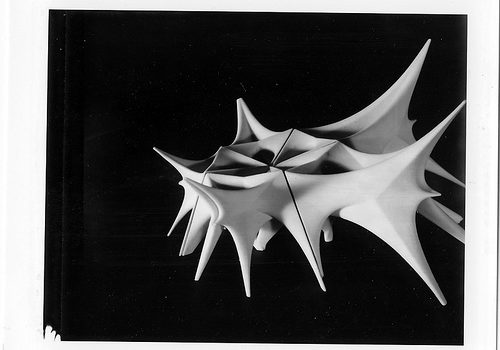

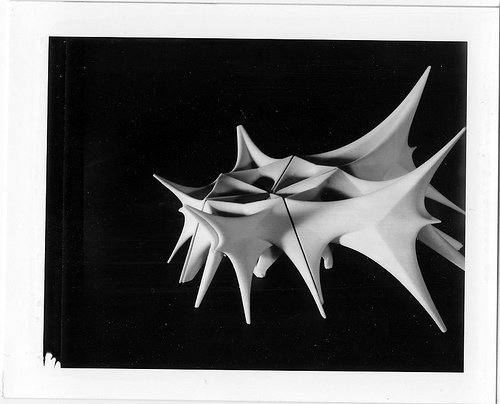

Approaches and apparatus supply a means to swiftly develop and modify speedy prototype surface coverings for customer review and approval, and fill the commercial pipeline even though a lot more standard production gear is obtained, installed and tested. The present apparatus to speedy prototype and fill the commercial pipeline includes a digital printing method to print a film and a press for laminating and embossing the printed film to a substrate. The press makes use of an embossing plate or roll, which is produced from ebonite or by three-dimensional printing gear. These plates and rolls can be produced within two or three days or much less.

A technique of speedy prototyping and manufacture of surface coverings obtaining a substrate, a print layer and a put on layer, the strategy comprising: a. producing aprototype surface covering making use of a digital printing program to print the print layer and a press to emboss the wear layer, wherein the press comprises an embossing tool chosen from the group consisting of an embossing plate and an embossing roll, theembossing tool produced by 3-dimensional printing, and b. utilizing the digital printing system and press to fill the commercial solution pipeline.

Developing new styles for surface coverings, by producing a prototype to show a possible consumer prior to making a mass produced product available, is high-priced and usually requires three months or more. This is mainly due to the price and timeto create print cylinders and embossing cylinders.

Consumers are demanding shorter and shorter improvement instances and far more input into the final style of the item. It would be advantageous to have a signifies to swiftly (within a matter of days) modify a design and style, produce a prototype that willfaithfully imitate the final item, and be capable of producing industrial quantities of the final item at a rate to meet initial commercial demand.

Existing approaches of prototyping surface covering are costly, due to the fact each and every change in design and style requires the rotogravure printing cylinder and the common embossing roll to be re-etched or re-engraved. If the surface covering is chemicallyembossed, any modify in the chemical embossing also demands re-etching or re-engraving of the print cylinder. The approach of remaking the cylinders is costly and time consuming.

The present invention overcomes this disadvantage by using digital printing to make speedy adjustments in the print pattern and chemical embossing pattern. The chemical embossing pattern is developed by printing a blowing agent modifier, such as ablowing inhibitor or a blowing accelerator.

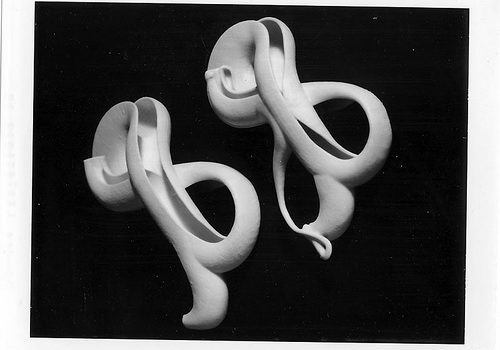

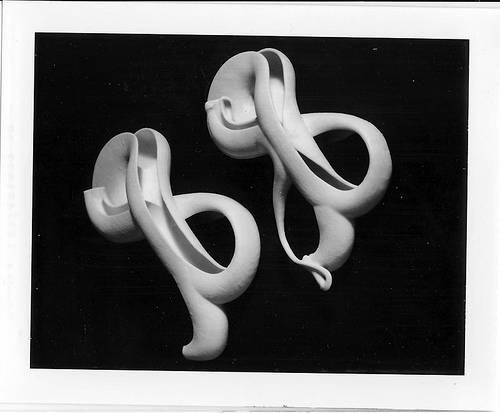

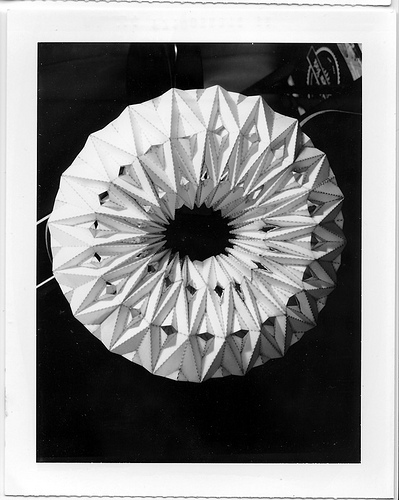

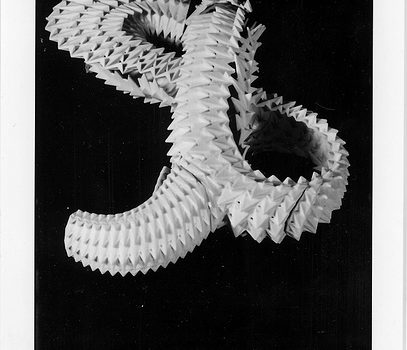

The present invention also uses mechanical embossing tools that can be made within two or 3 days. The embossed plates used in a stacker press are less expensive and faster to make than the conventional mechanical embossing rolls utilised in thetypical manufacture of tile and sheet goods. Ebonite embossing cylinders and embossing plates, and cylinders and plates made by three-dimensional printing gear can also be created inside two or three days. For that reason, the fast prototyping of thesurface covering necessary by the present invention is achieved.

Additional, time to industry is drastically shortened by using the digital printing system, stacker press, ebonite mechanical embossing cylinders and plates, or mechanical embossing cylinders and plates made by three-dimensional printing equipmentto fill the commercial item pipeline. Whilst the pipeline is becoming filled, the classic rotogravure printing cylinders and mechanical embossing rolls can be created, and the less costly to manufacture production line, which includes the rotogravureprinting cylinders and mechanical embossing rolls, can be set up. After the rotogravure printing and mechanical embossing line is up and running, the digital printing method and stacker press, ebonite embossing rolls or three-dimensional printing rollsmay be utilized to create an additional new tile or sheet goods.

In a preferred embodiment, the prototypes and industrial solution which fills the industrial pipeline makes use of a digital printing system and an embossing technique in which the embossing tool can be produced inside two or 3 days. The digital printingsystem permits fast and versatile altering of the prototype style.

Although the prototyping embossing systems that are envisioned create tile at a slower rate than standard tile manufacturing lines and do not use an embossing tool having a extended commercial production lifespan, the tools can be created within two orthree days and are durable enough to make sufficient industrial solution to fill the commercial pipeline and permit time to manufacture and set up the standard commercial embossing tools.

1 goal of this invention is to enable the user to speedy prototype and/or manufacture vinyl tiles T, either the regular residential sort D.I.Y. vinyl tiles or luxury vinyl tiles sheet goods S, which includes residential and commercialresilient flooring and other surface coverings, specifically those that are printed and mechanically embossed. At present, the manufacturing procedure utilized to develop and make vinyl tile and sheet goods can take as lengthy as 90 days. The presentinvention will significantly reduce the cycle-time to make such vinyl tiles and sheet goods to as brief as a single week or significantly less, thereby providing the user a considerable marketplace benefit.

We are The Leading 1 rapid prototype store,we sell speedy prototypes,you can purchase Safe Plastic mold from us.