Verify out these milling engineering pictures:

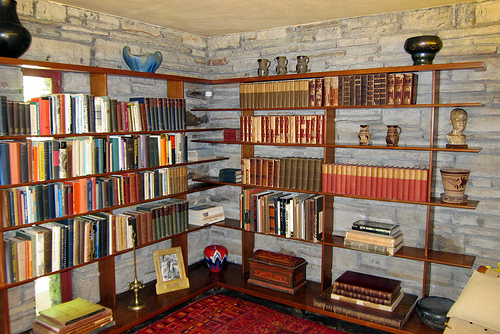

PA – Mill Run: Fallingwater – Kitchen

Image by wallyg

Modern for its day, the Fallingwater kitchen was equipped with St. Charles metal cabinets, a Swedish AGA stove, red asphalt tiles, and a Formica-topped work table designed by Wright. The Kaufmanns’ chef Elsie Henderson bought the state of-of-the-art turquoise-lined Imperial Cyclomatic CT150 Frigidaire in the 1950s. The Formica that tops the counters and Wright’s table was only patented in 1935, but Kaufmann learned of it early simply because it was invented locally by two engineers at Westinghouse.

Fallingwater, at times referred to as the Edgar J. Kaufmann Sr. Residence or just the Kaufmann Residence, positioned inside a 5,100-acre nature reserve 50 miles southeast of Pittsburgh, was designed by Frank Lloyd Wright and constructed amongst 1936 and 1939. Built over a 30-foot flowing waterfall on Bear Run in the Mill Run section of Stewart Township, Fayette County, Pennsylvania, the house served as a vacation retreat for the Kaufmann loved ones which includes patriarch, Edgar Kaufmann Sr., was a profitable Pittsburgh businessman and president of Kaufmann’s Division Retailer, and his son, Edgar Kaufmann, Jr., who studied architecture briefly beneath Wright. Wright collaborated with staff engineers Mendel Glickman and William Wesley Peters on the structural design, and assigned his apprentice, Robert Mosher, as his permanent on-web site representative throughout building. In spite of frequent conflicts between Wright, Kaufmann, and the building contractor, the property and guesthouse were finally constructed at a expense of 5,000.

Fallingwater was designated a National Historic Landmark in 1966. It was listed amongst the Smithsonian’s 28 Locations to See Ahead of You Die. In a 1991 poll of members of the American Institute of Architects (AIA), it was voted "the best all-time work of American architecture." In 2007, Fallingwater was ranked #29 on the AIA 150 America’s Favored Architecture list.

National Register #74001781 (1974)

PA – Mill Run: Fallingwater – Sitting Space

Image by wallyg

The Sitting Space at Fallingwater was added in 1946 just off the Kitchen underneath the cantilevered terrace to offer further space for servants in the Major Residence. A massive boulder punctuates the space, and the mitered-glass corner maintains Wright’s theme of transparency.

Fallingwater, sometimes referred to as the Edgar J. Kaufmann Sr. Residence or just the Kaufmann Residence, situated inside a 5,one hundred-acre nature reserve 50 miles southeast of Pittsburgh, was created by Frank Lloyd Wright and built in between 1936 and 1939. Built more than a 30-foot flowing waterfall on Bear Run in the Mill Run section of Stewart Township, Fayette County, Pennsylvania, the home served as a trip retreat for the Kaufmann family such as patriarch, Edgar Kaufmann Sr., was a profitable Pittsburgh businessman and president of Kaufmann’s Department Retailer, and his son, Edgar Kaufmann, Jr., who studied architecture briefly beneath Wright. Wright collaborated with employees engineers Mendel Glickman and William Wesley Peters on the structural style, and assigned his apprentice, Robert Mosher, as his permanent on-internet site representative all through building. Regardless of frequent conflicts amongst Wright, Kaufmann, and the construction contractor, the home and guesthouse had been lastly constructed at a price of 5,000.

Fallingwater was designated a National Historic Landmark in 1966. It was listed among the Smithsonian’s 28 Areas to See Before You Die. In a 1991 poll of members of the American Institute of Architects (AIA), it was voted "the best all-time perform of American architecture." In 2007, Fallingwater was ranked #29 on the AIA 150 America’s Preferred Architecture list.

National Register #74001781 (1974)