Product style and development is the term that encompasses the improvement, designing and manufacturing of the item. The methodologies have changed but the goal is still the identical. The modify of techniques has created this field a lot a lot more dependable and strong. Throughout the emerging days of this sector the solution designing was carried out through hand produced drawing and the prototypes that had been generated lacked accuracy.

Even although they lack accuracy and reliability, the item designing services were extremely costly and only huge players in the market place were in a position to avail this service. But with the building technology the accuracy and reliability of the generated prototype has improved and the expense of availing the service also becomes cheaper. Therefore, the new technologies for solution prototyping led to the much more dependable and precise solutions and at a very reasonable price tag.

One of the main benchmarks in the field of Item Prototyping was the introduction of Fast Prototyping tools such as Autodesk. The Autodesk application helped the designers to create a digital prototype of the solution and test the generated prototype also. With the improved version of this software it even inherits the feature to generate the 3D prototype of the solution defining the measurements and functions of each and every part.

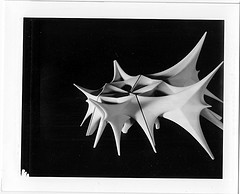

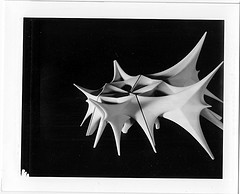

Then with the establishing era of Solution Designing Solutions there came an additional key achievement of 3D printing Prototyping. With the support of this technology the item can be visualized like a reside item. The generated prototypes of the solution have the same appear and feel as that of the original product. The 3D Model Printer is used to produce the models for the product employing the model printers. The solution design and improvement industries all more than the globe have adapted these newest prototyping services and these who are still stuck to the old approaches are facing a great reduction in their clientele.

Unlike the earlier prototyping technique, these Rapid Prototyping strategies have created the perform simpler for solution improvement. When handmade styles had been employed, accuracy factor was significantly missing in many of the prototypes as a outcome of which the development group employed to work upon the accuracy and they have to operate for both developing the product as properly as to eradicate the errors.

These most current prototyping tactics have created it less difficult for designers to inherit accuracy in the generated prototype as nicely as they can test the prototype too which increases the level of accuracy and make the solution prototype fairly reputable for designers, client and improvement team.

WB Engineering was established in fall 2007, since then has been growing year after year by increasing its capabilities and consumer base. Our staff consists of engineers with varying backgrounds, which includes Biomedical, Mechanical and Electrical Engineering. With in home capabilities for digital and fast prototyping using the newest and most sought after technologies