Some cool sheet metal elements images:

Tupolev Tu-four

Image by Peer.Gynt

Monino Central Air Force Museum (Moscow) July 2010

The Tupolev Tu-4 (NATO reporting name: Bull) was a piston-engined Soviet strategic bomber that served the Soviet Air Force from the late 1940s to mid-1960s. It was a reverse-engineered copy of the U.S.-produced Boeing B-29 Superfortress.

Towards the finish of Planet War II, the Soviet Union saw the need for a strategic bombing capability equivalent to that of the United States Army Air Forces. The Soviet VVS air arm did have their own-design and style Petlyakov Pe-8 4-engined "heavy" in service at the start of the war, but only 93 have been built by the end of the war as the sort had been equipped with unreliable turbocharged V12 diesel engines at the commence of its service to give it extended variety. The U.S. often carried out bombing raids on Japan, really close to the Soviet Union’s borders, from distant Pacific forward bases using B-29 Superfortresses. Joseph Stalin ordered the improvement of a comparable bomber.

The U.S. twice refused to supply the Soviet Union with B-29s under Lend Lease. Nevertheless, on 4 occasions during 1944, person B-29s produced emergency landings in Soviet territory and one crashed soon after the crew bailed out. In accordance with the Soviet–Japanese Neutrality Pact, the Soviets had been neutral in the Pacific War and the bombers have been therefore interned and kept by the Soviets. Regardless of Soviet neutrality, America demanded the return of the bombers, but the Soviets refused. 3 repairable B-29s had been flown to Moscow and delivered into Tupolev OKB. One particular B-29 was dismantled, the second was utilized for flight tests and training, and the third one particular was left as a standard for cross-reference. With the Soviet declaration of war against Japan in accordance with the Yalta agreement to enter the war within 90 days of VE day (to let it time to move its forces from Europe to Asia) at about 11pm on August eight, 1945 — two days right after the U.S. bombing of Hiroshima and the subsequent entente with Japan ending, the fourth B-29 was returned to the US along with its crew.

Stalin tasked Tupolev with cloning the Superfortress in as brief a time as feasible as an alternative of continuing with his personal comparable ANT-64 or samolet (aircraft) 64, and Soviet sector was to generate 20 copies of the aircraft ready for State acceptance trials in just two years.

The Soviet Union used the metric technique, hence sheet aluminum in thicknesses matching the B-29’s imperial measurements have been unavailable. The corresponding metric-gauge metal was of various thicknesses. Alloys and other supplies new to the Soviet Union had to be brought into production. In depth re-engineering had to take place to compensate for the variations, and Soviet official strength margins had to be decreased to avoid further redesign,[9] yet despite these challenges the prototype Tu-four only weighed about 750 lb (340 kg) much more than the B-29, a distinction of much less than 1%.

The engineers and suppliers of elements were under stress from Tupolev, Stalin, and the government to generate an exact clone of the original B-29 to facilitate production and Tupolev had to overcome substantial resistance in favor of using equipment that was not only already in production but in some situations much better than the American version. Each and every component produced and each and every alteration was scrutinized and was subject to a lengthy bureaucratic method. Differences have been restricted to the engines, the defensive weapons, the radio (a later model used in lend-lease B-25s was employed in spot of the radio in the interned B-29s) and the identification buddy or foe (IFF) program – the American IFF getting unsuitable. The Soviet engine, the Shvetsov ASh-73 was a development of the Wright R-1820 but was not otherwise associated to the B-29s Wright R-3350. and the remote-controlled gun turrets were redesigned to accommodate the harder hitting and longer ranged Soviet Nudelman NS-23 23mm cannon. Kerber, Tupolev’s deputy at the time, recalled in his memoirs that engineers necessary authorization from a higher-ranking common to use Soviet-made parachutes. Extra changes had been created as a result of difficulties encountered during testing, associated to engine and propeller failures and equipment modifications had been produced throughout the aircraft’s service life. Despite the fact that it has been extensively quoted, the Tu-4 did not have a random hole drilled in the wing either to emulate a bullet hole or due to the fact a Boeing engineer made a mistake – the Russians had three total aircraft and the wreckage of a fourth and the likelihood of all four getting a hole in the same spot is as well small to be credible. The aircraft included 1 Boeing-Witchita −5-BW, 2 Boeing-Witchita −15-BWs and the wreckage of 1 Boeing-Renton −1-BN – 3 diverse models from two diverse production lines. Only 1 of the 4 had de-icing boots as utilised on the Tu-four.

The Tu-four 1st flew on 19 May 1947, piloted by test pilot Nikolai Rybko. Serial production started immediately, and the sort entered big-scale service in 1949. Entry into service of the Tu-four threw the USAF into a panic, because the Tu-4 possessed enough range to attack Chicago or Los Angeles on a 1-way mission, and this may have informed the maneuvers and air combat practice performed by US and British air forces in 1948 involving fleets of B-29s. Some attempts to develop midair refueling systems have been made to extend the bomber’s variety, but these have been fitted to only a few aircraft.

The aircraft was initial displayed during a flyover at the Aviation Day parade on three August 1947 at the Tushino Airport in Moscow. 3 aircraft flew overhead. It was assumed that these were merely the three B-29 bombers that were recognized to have been diverted to the USSR throughout Planet War II. Minutes later a fourth aircraft appeared. Western analysts realized that the Soviets must have reverse-engineered the B-29. The appearance of an clearly Superfortress-derived Tu-70 transport more than the crowd removed any doubt about the accomplishment of the reverse-engineering.

Eight hundred and forty-seven Tu-4s had been built when production ended in the Soviet Union in 1952, some going to China during the later 1950s. Many experimental variants were built and the beneficial experience launched the Soviet strategic bomber plan. Tu-4s were withdrawn in the 1960s, getting replaced by far more advanced aircraft: the Tupolev Tu-16 (beginning in 1954) and the Tupolev Tu-95 (beginning in 1956). By the beginning of the 1960s, the only Tu-4s nevertheless operated by the Soviets were utilized for transport or airborne laboratory purposes. A Tu-4A was the very first Soviet aircraft to drop a nuclear weapon, the RDS-1.

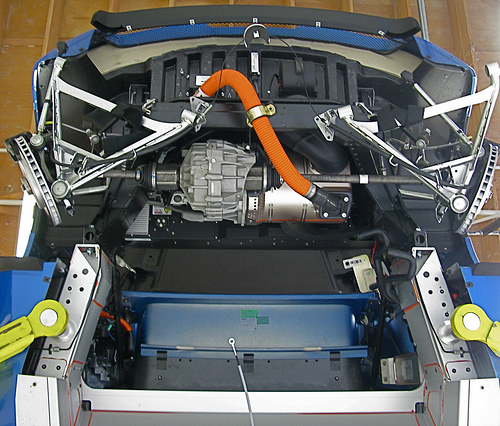

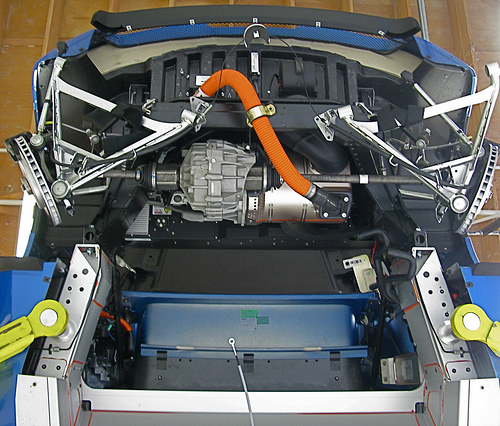

Santa’s Electric

Image by jurvetson

What a superb present from Tesla – the opportunity to drive the identical vehicle that I have had since August, but now with an completely new motor, inverter and gear box. They just upgraded me to Powertrain 1.5 and firmware 3.1.12

It’s much smoother and has the rail gun torque that I had read so a lot about. Also, the battery coolant pump now shuts down when parked (an irksome precaution in early models that is no longer required).

The fascinating back story is that a key redesign of the whole drivetrain was enabled by a breakthrough in the semiconductor market – a new IGBT (power transistor) that just began shipping. Advances in the smallest of components unlocked a design and style cascade to remove the need for shifting altogether (no transmission) while also improving efficiency (longer range, higher efficiency, 30% more torque, 14,000 RPM redline).

The Tesla weblog has the full story and gearbox photos from the CTO, J.B. Straubel.