Redditch, England (PRWEB UK) 1 October 2014

BCAS Limited’s information of compressed air systems and 25 years of expertise with the JUN-AIR variety of air compressors supplies a unique proposition for end users and OEMs, and one particular current and high-profile instance of this relationship has seen JUN-AIR compressors supplied to the laboratories of the technical department of the International Tennis Federation (ITF), the governing physique of the sport of tennis.

Commenting for BCAS Restricted, sales and advertising director Christine Peaden says: “BCAS Restricted is delighted to be operating with such a professional organisation as the International Tennis Federation (ITF). We also have each self-assurance in JUN-AIR as a premium brand – from top quality and functionality, by means of to help and personnel – and are usually satisfied to advocate their items to our consumers.”

As the International Tennis Federation’s sports engineer James Spurr explains, as in any sport, rules have to be established and enforced and the responsibility starts with governing bodies. “The mission of the ITF is to safeguard the nature of the game of tennis and we do that in a quantity of methods. A single essential element is to safeguard the expertise traditionally needed to play the game and our interpretation of that is when on court, you want the greatest player to win, not necessarily the player with the very best equipment!

“It may then come as a surprise to several, but the document describing the guidelines of tennis is pretty tiny and, whilst such as the familiar rules, it also details the gear that players can use at official tournaments.”

Even so, although guarding tennis and ensuring it can be enjoyed by both players and spectators, the governing body also has a responsibility to encourage innovation inside the game. The ITF’s technical department and its laboratories are therefore solely focussed on gear, such as the ball and racquet, and must ensure that regulations are met. At the very same time it should also encourage producers to be innovative, as it is in their greatest interests and these of the sport, to develop new technologies.

“Innovation is encouraged at the International Tennis Federation,” says James. “But we should guarantee that evolution does not become revolution simply because competitors and spectators are generally uncomfortable with that and there are examples from other sports where such modify has occurred and governing bodies have had to step in and retrospectively make adjustments to the guidelines.”

The ITF’s laboratories apply a quantity of fixed and mobile devices to test tennis balls and racquets and take direct measurements such as court speed. The outcomes are employed to investigate exactly where functionality comes from – how the modern day tennis player interacts with the ball utilizing speed and spin how the ball interacts with the numerous playing surfaces and how the player moves about the court. However, the one core objective of the ITF’s laboratory is ball approval.

To make sure that tennis balls can be used at official tournaments such as Wimbledon and the Australian and US Opens, companies submit samples of around 300 various ball brands to guarantee that each and every design and style falls within the ITF’s specification of a tennis ball, and as a result acquire the all-essential ITF-approved status. Here, tests are pneumatically driven utilizing compressed air from JUN-AIR oil-free and oil-lubricated compressors.

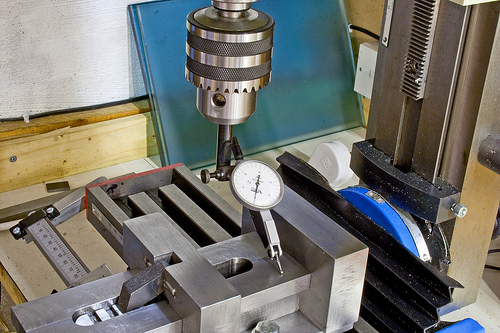

Here, automated machines utilizing oil-lubricated 12-25 JUN-AIR compressors are loaded with up to 12 tennis balls to be tested for stiffness. Pneumatic grippers move tennis balls from a carousel onto two electro-mechanical platens, which stress and measure each and every ball a quantity of instances on their numerous axes. Another durability test uses compressed air powered cannons driven by oil-totally free OF302-4B JUN-AIR compressors to fire six tennis balls 20 times onto a steel surface at 90mph (the standard speed of a forehand return or second serve). This replicates their standard usage more than nine games. As the balls degrade with use and turn into lighter and as the compound breaks down and the felt wears, a secondary bounce test measures rebound height from a 2.5m-drop, soon after which the balls are returned to the platen-primarily based deformation machine for further testing.

The technical division is also accountable for conducting field tests at places all more than the globe and ahead of major tournaments such as the Davis Cup and the Fed Cup. Right here, the team has access to eight transportable oil-free of charge JUN-AIR compressors (which includes four of the company’s transportable i40-4B iSeries models) contained in flight cases.

Court Pace Rating (CPR) – the speed of the court – is measured utilizing a related cannon-based setup as the laboratory. Making use of compressed air, tennis balls are fired at around 75mph onto eight diverse areas of the court, which can be grass, clay or acrylic surfaces. The ball is fired in between two light-gates to measure the horizontal and vertical elements of the ball speed prior to and following effect. Right after some number crunching, the CPR is a number between and one hundred (but preferably among 24 and 50) that determines if the court pace falls within the permitted parameters for a tournament.

“The explanation for field testing of court speeds is to avoid the threat of injury or accidents linked with low-friction courts and to avoid any one nation obtaining as well a lot property benefit by practising on a court that is slower or more quickly than those of the going to nations.” says James.

Fortunately, as tests are generally carried out in the days/weeks ahead of a tournament, if the court is deemed too fast or slow and for that reason as well harmful to play on, it can be replaced inside hours and additional tests carried out. Even so, in extreme situations the host nation could forfeit the matches, or be penalised financially or through the deduction of group points.

Commenting on the compressors’ overall performance, James says: “Ball tests are carried out everyday in the course of the laboratories’ busy periods so the JUN-AIR compressors are effectively employed. Nonetheless, apart from routine upkeep and inspections, for the duration of which oil levels on the oil-lubricated compressors are checked and topped up if essential air tanks drained of water and air filters cleaned of debris from the balls’ felt covering, we have in no way had a failure and the compressors are always running nicely.”

The JUN-AIR OF range of oil-significantly less air compressors offer you an unrivalled mixture of low noise levels, reliability, extended life and low maintenance. With decibel ratings as low as 47dB(A) when housed in appealing soundproof cabinets, models in the OF oil-less range have the lowest noise levels available, producing them perfect for installations inside laboratory environments and even in or near individual workstations.

The compact and self-contained JUN-AIR iSeries compressed air package consists of a rocking piston compressor and air receiver and is offered with three compressor combinations and two distinct tank sizes, offering airflow rates from 28 to 56 lpm at 7 bar, a maximum stress rating of 7 bar and tank sizes from four to 25 litres.

With noise levels under 45 dB(A), the JUN-AIR oil-lubricated piston compressor variety comprises nine models offered in mixture with 5 different receivers (from 4 litres to 150 litres) to generate a wide variety of full compressor offerings.

Commenting for Gast Group, European sales director Andre Goodson says: “We are delighted to be involved with such a higher-profile sporting body and grateful to BCAS Restricted for delivering the International Tennis Federation with professional guidance on the JUN-AIR item and its on-going servicing and maintenance. Their 25 years of experience with JUN-AIR puts them in an enviable position and we think that the mixture of BCAS’s knowledge of compressed air systems and Gast Group’s vast range, provides the partnership a distinctive proposition for finish users and OEMs.”

For further info contact Gast Group on +44 ()1527 504040, e mail gastgroup.uk(at)idexcorp(dot)com or check out http://www.jun-air.com.