Metal casting strategy means the casting processes, which make the metal supplies into designed metal goods. Casting is the most simple and the most frequently utilized metal manufacturing technologies.

According to the distinct casting materials, casting strategies can be divided into black metal casting (like cast iron, cast steel) and nonferrous metal casting (including aluminum, copper alloy, zinc alloy, magnesium alloy, etc.).

According to the different mold components, casting approaches can be divided into sand mold casting and metal mold casting.

Casting methods can also be divided into gravity casting and stress casting according to the various approach theories.

Gravity casting is the casting approach that pours the molten metal into the mold by the Earth’s gravity, also identified as pouring casting. Gravity casting strategy includes sand casting, metal mold casting, investment casting, lost foam casting and die casting.

Sand casting is a sort of metal casting method, whose major material is quartz sand. Sand casting is a conventional casting procedure. Sand casting is typically gravity casting, but if there are specific requirements, it also might be low stress casting or centrifugal casting process.

Sand casting has a wide adaptability, such as creating small castings, large castings, simple parts, complicated parts, single casting, large quantities of castings. The casting patterns of sand casting can be divided into wood pattern, resin pattern and metal pattern.

Metal mold casting strategy makes use of the heat-resistant alloy steel patterns as the casting molds, and the melted metal will be poured into the steel patterns straight. Metal mold casting methods can also be divided into gravity metal mold casting and pressure metal mold casting. The steel patterns of metal mold casting can be utilized repeatedly, each and every time pouring can get a casting, the steel patterns have a quite long lifetime, and the production efficiency is higher.

Metal mold casting method is not only a very good dimensional accuracy, surface finish, and the casting strength is larger than the sand castings, but also not effortless to damage. As a result, metal mold casting strategy is typically utilized for making non-ferrous metal castings.

Even so, the metal mold casting technique also has some disadvantages: The heat-resistant alloy steel patterns are quite costly, so for tiny batch production, the share to the expense of every single product is too higher on the mold, usually difficult to be accepted. Moreover, simply because the steel patterns have size limitation, so it also limit the size of castings. For that reason, for small quantities or huge size castings, normally do not use metal mold casting.

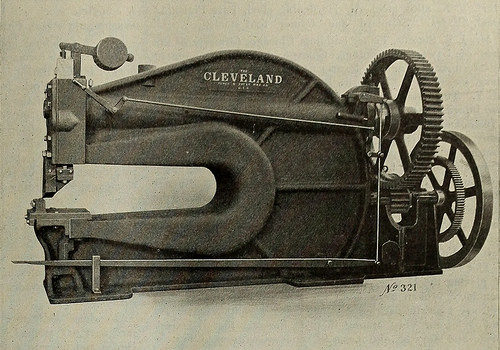

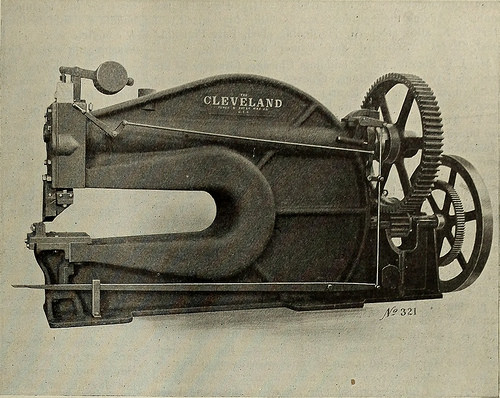

Die casting approach is a type of metal mold casting approach, but the melted metal is injected by pressure from die casting machines. Die casting machines are divided into hot chamber die casting machines and cold chamber die casting machines. Die casting machine has a high degree of automation, significantly less waste of materials, and larger efficiency than the cold chamber die casting machine, but due to the fact of the mechanical heat capacities, the hot chamber die casting machines are only for creating zinc alloy, magnesium alloy and other low melting point materials casting. Today’s widespread use of aluminum die casting, due to high melting point, only created in the cold chamber die casting machines.

In brief, all metal casting approaches have their own positive aspects and disadvantages. According to the difference of the solution components, applications and needs, buyers need to decide on the appropriate casting strategy.

This write-up was from Dandong Foundry Weblog.

http://www.iron-foundry.com/casting-approach.html

Associated Die Casting China Articles