A few good stamping parts china photos I found:

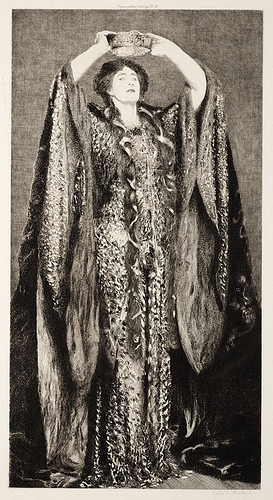

Portrait of Ellen Terry as “Lady MacBeth” (Etching, 1895)

Image by Toronto Public Library Specific Collections

Title: Portrait of Ellen Terry as ‘Lady MacBeth’

Medium: Original etching

Artist: primarily based on John Singer Sargent oil portrait 1889 (United States, 1856-1925)

Engraver: Gaston Albert Manchon (France, Born 1855)

Publisher: George Barrie, Philadelphia

Date: 1895

This image is portion of the Ellen Terry collection.

Place: Toronto Reference Library, Performing Arts Centre

Rights: Public domain

Art Exhibited at the World’s Columbian Exposition and George Barrie:

From 1893 to 1895 the Philadelphia printer and publisher, George Barrie, was at operate upon a massive and lavish series of original etchings and chromolithographs detailing exhibits of the fine art from participating nations at the World’s Columbian Exposition.

The original prints, such as this fine example, have been printed on either China or Japon papers and were restricted to an edition of only two hundred impressions. Barrie hired some of the finest etchers of the time to operate on the series.

These days these original etchings and lithographs are collected not only for their important 1890’s style but for their superb technical accomplishments

Image Size: 18" X 12 1/5" (to edge of margins)

Condition: Superb. Printed on fine China paper and impressed onto a bigger sheet of white, wove paper. Bearing the official blindstamp of the World’s Columbian Exposition to the lower left. All blind stamped with seal of 1893 World Columbia Expositionrom From a site … not positive it applies to ours

Description: (Sargent, Shakespeare, Ellen Terry-Actress)

Feasible supply – 1893 Columbian Exposition Art and Architecture

By William Walton – Volume 1 The Art – published by George Barrie Philadelphia. "

1942 Admiral Togo with Surcharge marking the Surrender of Singapore

Image by Vintage Lulu

The four Sen Green depicting Admiral Togo was first issued in 1937. This stamp bears a surcharge "+ 2 Sen" to mark the Surrender of Singapore which dates it to 1942.

Togo was a Fleet Admiral in the Imperial Japanese Navy and one of Japan’s greatest naval heroes. He was termed by Western journalists as the ‘Nelson of the East’.

Tōgō was born on 27 January 1848 (by the Western calendar) in the city of Kagoshima in feudal Japan. Tōgō’s father was a samurai, serving below the property of Shimazu, and he had 3 brothers.

Kachiyacho was one particular of Kagoshima’s samurai housing-districts, in which a lot of other influential figures of the Meiji period had been born, such as Saigō Takamori and Ōkubo Toshimichi. They rose to prominent positions beneath the Meiji Emperor partly due to the fact the Shimazu clan had been a decisive military and political aspect in the Boshin war against the Tokugawa Shogunate and in the Meiji Restoration.

Tōgō’s initial combat expertise was at the age of 15 throughout the Anglo-Satsuma War (August 1863), in which Kagoshima was bombarded by the British Royal Navy to punish the Satsuma daimyo for the murder of Charles Lennox Richardson on the Tōkaidō highway the earlier year (the Namamugi Incident), and the Japanese refusal to spend an indemnity in compensation.

The following year, Satsuma established a navy, in which Tōgō and two of his brothers enrolled. In January 1868, during the Boshin war, Tōgō was assigned to a paddle-wheel steam warship, Kasuga, which participated to the Naval Battle of Awa, close to Osaka, against the navy of the Bakufu, the first Japanese naval battle amongst two contemporary fleets.

As the conflict spread to northern Japan, Tōgō participated as a third-class officer aboard the Kasuga in the final battles against the remnants of the Bakufu forces, the Naval Battle of Miyako and the Naval Battle of Hakodate (1869).

Tōgō studied naval science for seven years in England as an apprentice officer, from 1871 to 1878, collectively with sixteen (or eleven?) other Japanese students. Tōgō visited London, at that time the largest and most populous city in the planet. Several things were strange to Japanese eyes the round houses made out of stone, the ‘number and massiveness of the buildings’, ‘the furnishings of a commonplace European room’, ‘the displays in the butchers’ shop windows: it took them many days to grow to be accustomed to such an abundance of meat.’ The Japanese group was separated and sent to English boardinghouses for person instruction in English language, customs and manners. Next, Tōgō was sent to Plymouth, exactly where he was assigned as a cadet on HMS Worcester, which was element of the Thames Nautical Instruction College, in 1872. Tōgō identified his cadet rations ‘inadequate’: "I swallowed my small rations in a moment. I formed the habit of dipping my bread in my tea and eating a excellent deal of it, to the surprise of my English comrades." This was attributed possibly to Tōgō’s ‘Far Eastern metabolism’, the lack of rice, ‘or that some other essential element was missing or maybe the climatic differences sharpened his appetite.’ Probably the excitement of his adventure contributed, or possibly Togo just liked the meals. Togo’s comrades known as him ‘Johnny Chinaman’, getting unfamiliar with the ‘Orient’, and not being aware of the distinction amongst Asiatic peoples. ‘The young samurai did not like that, and on a lot more than one occasion he place an end to it by blows.’ Tōgō also shocked these young Englishmen by graduating second in the class.

For the duration of 1875, Tōgō circumnavigated the globe as an ordinary seaman on the British coaching-ship Hampshire, leaving in February and staying seventy days at sea with out a port contact till reaching Melbourne, consuming only salted meat and ship’s biscuits. Tōgō ‘observed the strange animals on the Southern continent.’ On his return, Tōgō had sailed thirty thousand miles. Tōgō suffered a strange illness which severely threatened his eyesight: ‘the patient asked his healthcare advisers to "try almost everything", and some of their experiments have been very painful.’ Mr. Capel commented later, ‘If’, he wrote, ‘I had not seen with my personal eyes what a Japanese can suffer with out complaint, I must frequently have been disinclined to believe….But, getting observed Tōgō, I think all of them.’ The Harley Street ophthalmologists saved his eyesight. Tōgō studied mathematics in Cambridge (although not at the University) throughout this time, although living with Reverend A.S. Capel. Tōgō then went to the Royal Naval Academy in Portsmouth, and to the Royal Naval College, Greenwich. For the duration of his stay, the Imperial Japanese Navy placed orders in Fantastic Britain for three warships. Tōgō created use of the chance to apply his instruction, supervising (watching meticulously) the building of the Fusō whilst on function encounter at the Samuda Brothers shipyard on the Isle of Dogs.

Tōgō, newly promoted to lieutenant lastly returned to Japan on 22 May possibly 1878 onboard a single of the newly-bought British-built ships, the Hiei.

Tōgō was absent from Japan for the duration of the Satsuma Rebellion, and typically expressed regret for the fate of his benefactor Saigō Takamori.

Franco-Chinese war (1884-1885)

Back in the Imperial Japanese Navy, Tōgō received many commands, very first as captain of Daini Teibo, and then Amagi. Throughout the Franco-Chinese War (1884-1885), Tōgō, onboard Amagi, closely followed the actions of the French fleet beneath Admiral Courbet.

Tōgō also observed the ground combat of the French forces against the Chinese in Formosa (Taiwan), beneath the guidance of Joseph Joffre, future Commander-in-Chief of French forces throughout World War I.

Sino-Japanese war (1894-1895)

Japanese Admiral Tōgō at the age of 55, shortly prior to the Russo-Japanese WarIn 1894, at the starting of the Initial Sino-Japanese War, Tōgō, as a captain of the cruiser Naniwa, sank the British transport ship, Kowshing, which was charted by the Chinese Beiyang Fleet to convey troops. A report of the incident was sent by Suematsu Kencho to Mutsu Munemitsu.

The sinking practically triggered a diplomatic conflict amongst Japan and Great Britain, but it was finally recognized by British jurists as in total conformity with International Law, producing Tōgō popular overnight for his mastery of contentious issues involving foreign nations and regulations. The British ship had been ferrying hundreds of Chinese soldiers towards Korea, and these soldiers had mutinied and taken over the ship upon the look and threats from the Japanese ships.

He later took element in the Battle of the Yalu, with the Naniwa as the last ship in the line of battle below the overall command of Admiral Tsuboi Kozo. Togo was promoted to rear admiral at the finish of the war, in 1895.

Following the finish of the Sino-Japanese War, Tōgō’s career was not so prominent. He was successively commandant of the Naval War College (Japan), commander of the Sasebo Naval College, and Commander of the Standing Fleet.

Russo-Japanese War (1904-1905)

Admiral Tōgō on the bridge of the battleship Mikasa, at the starting of the Battle of Tsushima, in 1905In 1903, the Navy Minister Yamamoto Gonnohyoe appointed Tōgō Commander-in-Chief of the Combined Fleet of the Imperial Japanese Navy. This astonished many folks, which includes Emperor Meiji, who asked Yamamoto why Tōgō was appointed. Yamamoto replied to the emperor, Since Tōgō is a man of very good fortune.

For the duration of the Russo-Japanese War, Tōgō engaged the Russian fleet at Port Arthur, in 1904, and destroyed the Russian Baltic Fleet in 1905, at the Battle of Tsushima, shocking the world with the strategic upset. This historic battle broke Russian strength in East Asia, and is also mentioned to have triggered numerous uprisings in the Russian Navy (1905 uprisings in Vladivostok and the Battleship Potemkin uprising), contributing to the Russian Revolution of 1905.

There was an investigation of the Russian naval leadership of the expedition, which Tōgō had destroyed or captured, into the reasons behind their utter defeat. The Russian commander of the destroyed Baltic fleet, Admiral Zinovi Rozhdestvenski (who was badly wounded in the battle) attempted to take full blame for the disaster, and the grateful authorities (and rulers of Russia) acquitted him at his trial. Nevertheless, they produced Admiral Nikolai Nebogatov, who had attempted to affix blame to the Russian Government a scapegoat. Nebogatov was discovered guilty, sentenced to ten years imprisonment in a fortress, but was released by the Tsar soon after only serving 2 years.

In 1906, Tōgō was produced a Member of the British Order of Merit by King Edward VII.

Later, Tōgō was Chief of the Naval General Employees and was given the title of hakushaku (Count) beneath the kazoku peerage program. He also served as a member of the Supreme War Council.

In 1913, Tōgō received the honorific title of Fleet Admiral.

From 1914 to 1924, Tōgō was put in charge of the education of Prince Hirohito, the future Showa Emperor.

He expressed a dislike and disinterest for involvement in politics even so, he did make robust statements against the London Naval Treaty.

Captain Sempill showing a Sparrowhawk to Admiral Tōgō Heihachiro, 1921.Tōgō was awarded the Collar of the Supreme Order of the Chrysanthemum in 1926, an honor that was held only by Emperor Showa and Prince Kan’in Kotohito at the time. He added the award to his current Order of the Golden Kite (1st class) and already existing Order of the Chrysanthemum. His title was raised to that of koshaku marquis in 1934 a day just before his death.

On his death in 1934 at the age of 86, he was accorded a state funeral. The navies of Wonderful Britain, United States, Netherlands, France, Italy and China all sent ships to a naval parade in his honor in Tokyo Bay.

The Togo Shrine, in Harajuku, Tokyo, Japan.

Tōgō Gensui kine kōen

Chiyoda, TokyoIn 1940, Tōgō Jinja was built in Harajuku, Tokyo, as the naval rival to the Nogi Shrine erected in the honor of Imperial Japanese Army Basic Nogi Maresuke. The idea of elevating him to a Shinto kami had been discussed before his death, and he had been vehemently opposed to the thought. There is another Tōgō shrine at Tsuyazaki, Fukuoka. The statues to him in Japan include one particular at Ontaku Shrine, in Agano, Saitama and a single in front of the memorial battleship Mikasa in Yokosuka.

Tōgō’s son and grandson also served in the Imperial Japanese Navy. His grandson died in combat throughout the Pacific War on the heavy cruiser Maya at the Battle of Leyte.

五智国分寺三重塔/gochi Kokubun Temple’s 3-story pagoda

Image by Kurosawa Michiyo

Please Follow my web page(s):

Facebook-

www.facebook.com/KurosawaMichiyoOfficial

Twitter:

twitter.com/KrswMichiyo

Description:

Region:五智国分寺/Gochi Kokubun temple

Place: 直江津/Nauetsu

District: 五智/Gochi

City上越市/Joetsu-shi

County: 新潟県/Niigata-ken

Country: 日本/Japan

Device makes: Canon

Device Model: Canon EOS 5D

Device Lens: Canon EF 24-105mm f/four L IS USM

Photographer: 黒澤 実千代「コニー」/Kurosawa Michiyo [Connie]

新潟県 のスタンプ/Niigata- ken stamps:

www.flickr.com/photographs/adore-gothiconnie/sets/7215762768149…

五智国分寺のスタンプ/Gochi Kokubun temple stamps:

www.flickr.com/pictures/enjoy-gothiconnie/6224728361/in/set-…

© 2013 Kurosawa Michiyo

注釈:

直江津越後五智国分寺:

今から1200年程前の天平13年に聖武天皇が日本の平和と繁栄を祈願して、その国ごとに国分寺と国分寺尼寺を建立された越後の国の国分寺です…

詳述:

www5c.biglobe.ne.jp/~etigo/

注釈:

三重塔:

三重の塔は、寛政6年の火災以後、安政3年(1856)に宮大工曽武川常右衛門、江崎長三郎の手により着工されました。その後、慶応元年(1865)に上棟され整備されてきましたが、高欄などが未完成のまま現在に至っております。また、塔の壁面には高田の名工石倉正義銘の十二支と中国十二孝の半分の彫刻がはめ込まれています。

Annotation:

Nauetsu Echigo gochi Kokubun Temple:

Fore much more detail [JP]:

www5c.biglobe.ne.jp/~etigo/

Pagoda:

a tiered tower, constructed in the traditions originating in historic East Asia or with respect to those traditions, with numerous eaves widespread in Nepal, India, China, Japan, Korea, Vietnam, Burma and other components of Asia.

For a lot more:

en.wikipedia.org/wiki/Pagoda

Note: Apologize for the limited photograph size. It is due to the fact of the copyright. (^u^)/

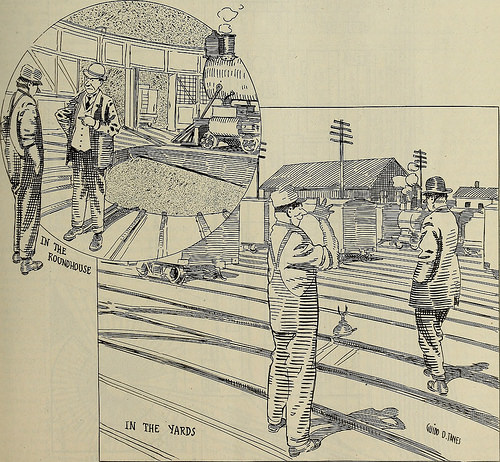

![Image from web page 342 of “Railway master mechanic [microform]” (1895) Image from web page 342 of “Railway master mechanic [microform]” (1895)](https://www.precisiontype.com/blog/wp-content/uploads/2016/09/14761630565_a4c5a2b09c-500x350.jpg)